Dies and Techniques used in Die Cutting

Selecting a production method for a given design can be a daunting task. Out of the myriad of choices available for the designer, die cutting often results in economical, accurate and repeatable production. Once die cutting is selected as the preferred manufacturing technique, the process of die selection can begin. Different types of dies such as steel rule dies, rotary dies and male/female tooling, all offer unique advantages, and which option production selects can influence the end result in many different ways. Here we will take a look at the most common types of die cutting tools employed by Colvin-Friedman, and talk a bit about what makes each of them unique.

Let’s begin with steel-rule dies. Perhaps the most economical option available, steel rule dies begin life as an ordinary piece of plywood. Using only the highest quality, knot free plywood available helps ensure a parallel, even surface for which to base the die in. Advanced tool makers will utilize a laser cutting system to cut the shape of the desired part out of the plywood, with slits that mirror the exact thickness of the rule being used. The actual type of steel rule selected for a given part may differ based on the thickness of the substrate being cut, the complexity of given features in the part, and common best practice for the firm selecting to have the tool made. The most common type of steel rule utilized by Colvin-Friedman is 4pt, left-center-bevel, 0.937” high rule, however there is no shortage of different styles and types of rule available. This rule is then inserted into the laser cut holes, and the beveled sharpened cutting ends emerge from the top of the plywood. The simplest analogy for this type of die is a household cookie-cutter. The process works much in the same way in that material is placed upon the shape, and using pressure and time, the shape is cut out of the material. The low cost and high accuracy of this tooling option positions steel rule dies as the frontrunner for many different custom die cutting jobs.

Thinner materials and higher volume production runs may take advantage of what are known as rotary dies. This type of tooling consists of a hardened steel cylinder, on the face of which the desired part design is etched and sharpened, allowing material which passes below it at high speed to be cut to the desired part shape. Rotary dies cut against a hardened anvil by burst fracturing the material. Depending on the complexity of the part, there are many different types of rotary die solutions offered, such as magnetic cylinders with chemically etched plate tooling, radially drilled pulse air dies, vacuum insert punch dies and many more. Employing industry leading servo driven press technology, chem etch tooling can be utilized to keep the cost burden of rotary technology low, while still taking advantage of the higher throughput achieved on a rotary platform. For thicker substrates such as non-wovens and plastics however, traditional fully hardened steel tooling is the preferred route. While the upfront cost of these dies exceeds that of steel rule die cutting, the resulting increase in throughput will pay for the difference in tooling in short order.

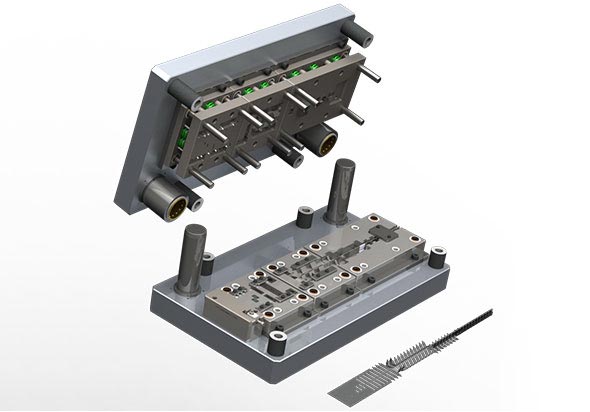

The third tooling option we will discuss is known as male/female reciprocal tooling. This type of tooling involves a female base, in which the top male portion forces material into, then being returned to the top position via springs and bushings. Advantages here lie in the wide range of substrates that can be cut, including metals, plastics, felts, and pretty much anything else. Commonly, these tools will use a shear cutting method, instead of the burst fracture method used in rotary/steel rule cutting. Material stops can hold the substrate in place during the cut, allowing for very tight tolerances, and superior edge quality. These tools need to be manufactured by a custom tool and die maker, and are some of the more expensive options available. They are best suited for jobs with highly complex features, very tight tolerance requirements, and very fine edge quality requirements.

Die Cutting Services

The combination of all tooling options mentioned in this article give production a wide variety of choice when matching a given part design to a production method. Colvin-Friedman has spent years perfecting the art of using each of these types of tools, which has positioned us as one of the preeminent suppliers of custom die cutting services. Give our salesmen a call today to go over which tooling option is best suited for your custom die cutting requirements!

Related Reading- All About Die CuttingDie Cutting is an intricate process that uses a die to cut webs or sheets of material such as plastic, rubber, foil, cloth, paper, foam, and many others.

- Why Is Die Cutting The Right Choice?

- Where Can You See Die Cutting in Everyday Life?