Planning for Die Cutting Services in California

Manufacturers and engineers have several options when utilizing commercial die cutting services. Knowing about the basic differences between these forming methods makes it easier to decide your manufacturing process. Below, we want to highlight two of the most popular die cutting processes and how they differ. The more you know about flatbed and rotary die cutting, the easier it is to choose which service is best for you.

Before getting into the differences between flatbed and rotary die cutting CA, we want to highlight what to consider when making your choice. You need to be able to answer these questions:

Before getting into the differences between flatbed and rotary die cutting CA, we want to highlight what to consider when making your choice. You need to be able to answer these questions:

- What is the thickness of the material you are processing?

- What is more important, cost of tolerance levels?

- How large of a run are you processing?

- Will you need kiss-cutting?

- Rotary die cutting is often seen as the most used die cutting method. It would help if you used it when processing thin materials. Rotary die cutting allows for kiss-cutting, and it can easily process large quantities of products.

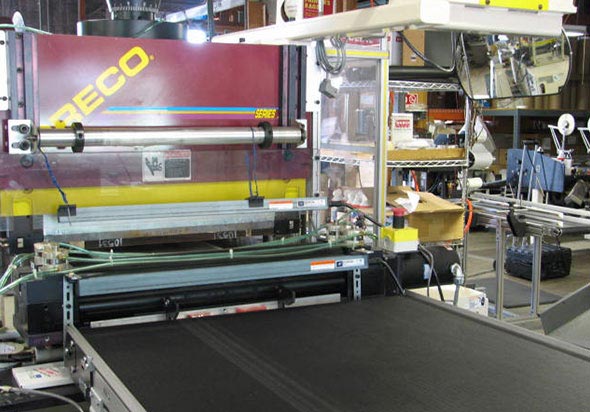

- Flatbed die cutting is better suited for thick materials in sheet form. This type of die cutting works best with a short run process, and it is often seen as the more cost-effective option. Flatbed die cutting utilizes a vertical motion for processing thick materials. As a result of the vertical motion, there is minor curvature in the material.

Die Cutting CA

Determining the correct die cutting method for an application is difficult, so if you still need help figuring out processes, you should not hesitate to give our team a call.

Related Reading: