Is Rotary Die Cutting a Versatile Fabrication Option

Die cutting CA offers many manufacturing processes for highly customizable final parts. Flatbed and rotary die cutting, as a manufacturing method, is versatile, allowing manufacturers to perform multiple operations using only a single cutting machine. This is achieved by replacing interchangeable dies. There are many different die configurations, and most of them are named for the type of work they perform. Below, we want to go over the most common die types and their work.

BENDING – during burning, materials are deformed by applying pressure from a die. These dies can create an L shaped bracket design, where the die descends over the materials to curve it to a 90-degree angle.

BLANKING – this forming process cuts flat materials by trimming the exterior edge. A blanket die works by compressing uniformly over the material, creating an exact degree of flatness.

BULGING – this is a fluid die that uses either oil or water to manage expanding parts. For instance, bulging rubber dies harness pressurized rubber blocks to deform a workpiece.

COINING – this process is like stamping. This type of die punches circular holes through materials. Cuts are often made with a pressurized force clamping a custom die and punch. Manufacturers use coining when they need to produce highly intricate product features.

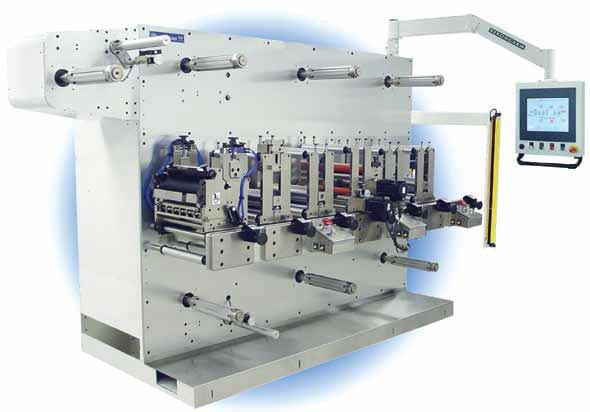

Rotary Die Cutting

ROLL FORMING – manufacturers used a series of deforming rolls that are processed at precise intervals. This offers a continuous stream of stock as it passes through the machinery. This forming method is ideal for fabricating long materials with unique cross-sectional designs.

Related Reading- Tips for Determining Die Cutting Project RequirementsReaching out for the best die cutting CA has will help you narrow down your options and create the perfect forming process.

- Understanding Creasing and Scoring

- What Industries Utilize Rotary Die Cutting