Best for high-volume production runs, thinner materials, and precision.

- 40,000 units/hour capacity

- 3-week average lead time

- ±0.005 inch tolerance level

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

We’re a family-owned custom die-cutting company with the capabilities and capacity of a large organization and the customer service of a small business.

On-Time Delivery Rate

Rejection Rate

Project Completion Rate

See why companies are trusting Colvin Friedman for their die cutting needs.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We are proficient in the following die-cutting services.

Best for high-volume production runs, thinner materials, and precision.

We hold raw materials for rapid response to customer demand fluctuations:

We offer the following converting capabilities:

Best for low to mid-volume production runs, thicker materials, and less demanding tolerances.

Best for high-volume production runs, thinner materials, and precision.

We hold raw materials for rapid response to customer demand fluctuations:

Colvin Friedman stands ready to assist in all aspects of your manufacturing process, from the design stage to full-scale production runs.

Our team will design a process to deliver precision parts to you repeatedly over the life cycle of your product.

With over 75 years of experience, we streamline material selection to ensure product quality.

Our team will aid in developing and testing a prototype model to ensure functionality within the final product.

Our team will design a process to deliver precision parts to you repeatedly over the life cycle of your product.

With over 75 years of experience, we streamline material selection to ensure product quality.

Our team will aid in developing and testing a prototype model to ensure functionality within the final product.

Our team will design a process to deliver precision parts to you repeatedly over the life cycle of your product.

With over 75 years of experience, we streamline material selection to ensure product quality.

Our team will aid in developing and testing a prototype model to ensure functionality within the final product.

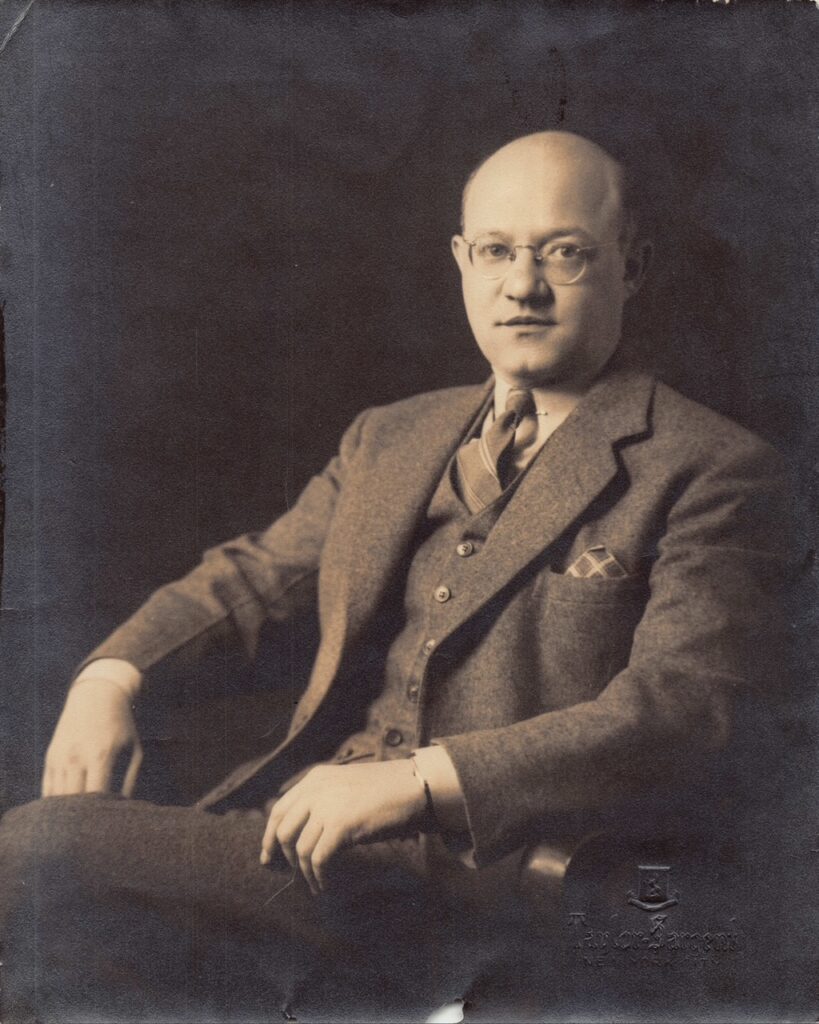

The Colvin-Friedman Company dates back to 1949, founded by Samuel Friedman and Henry Colvin. The pair had extensive backgrounds in plastic die cutting, fabrication, and decorating, forming Colvin Friedman to service the radio, television, and appliance industries. We became a leading supplier for companies such as RCA, Westinghouse, Philco, Emerson, and Edison Electric.

Our company has experience making custom, precision parts for a wide variety of industries. See the list below for more information.