Colvin-Friedman has been serving Los Angeles manufacturers who produce items across a wide scope of industries, from entertainment to defense to fashion, for more than 75 years. Finding the right die cutter for integrating within the supply chain of any of these products requires looking for a combination of experience, materials expertise, and an understanding of the Golden State regulatory and manufacturing landscape.

The wide variety of industries served by L.A. firms belies the fact that there are similarities in their needs for components. For example, high-tech firms and defense contractors alike benefit from die cutting suppliers who can handle fragile shielding and related materials while still producing within demanding tolerances. Below are some of the capabilities that Colvin-Friedman can bring to bear on each of the largest sectors in LA.

| Industry: Entertainment/Media | |

|---|---|

| Component | Description |

| Custom Packaging | Design and production of unique, die-cut packaging solutions for media products, promotional materials, and merchandise, enhancing brand presentation. |

| Set Design Components | Precision die-cut materials for set construction, including custom shapes and props. |

| Marketing Materials | High-quality die-cut brochures, posters, and other promotional items to support marketing campaigns. |

| Industry: Aerospace and Defense | |

|---|---|

| Component | Description |

| Gaskets and Seals | Manufacture of high-precision die-cut gaskets and seals from materials like rubber and foam, essential for aerospace applications. |

| Thermal and Acoustic Insulation | Die-cut insulation components that meet stringent aerospace standards for performance and safety. |

| Protective Covers | Custom die-cut protective films and covers for sensitive equipment and instruments. |

| Industry: High-Tech | |

|---|---|

| Component | Description |

| Electronic Components | Production of die-cut insulators, spacers, and EMI/RFI shielding materials for electronic devices. |

| Wearable Technology | Die-cut flexible materials for wearable tech, ensuring comfort and functionality. |

| Prototyping Services | Rapid die-cut prototyping to assist in product development cycles, enabling quick iterations and time-to-market. |

| Industry: Fashion and Apparel | |

|---|---|

| Component | Description |

| Fabric and Leather Cutting | Precision die-cutting of fabrics, leathers, and synthetic materials for apparel and accessories. |

| Brand Labels and Tags | Custom-shaped die-cut labels and tags that enhance brand identity. |

| Packaging Solutions | Attractive and functional die-cut packaging for clothing and accessories, improving product presentation. |

| Industry: Manufacturing | |

|---|---|

| Component | Description |

| Component Parts | Die-cutting of various materials to produce component parts for machinery and equipment. |

| Protective Equipment | Manufacture of die-cut safety gear components, such as face shields and padding. |

| Custom Gaskets and Seals | Production of die-cut gaskets and seals tailored to specific manufacturing requirements, ensuring optimal performance. |

Or call Josh at (707) 769-4488

Thanks to NAFTA and other trade agreements, many Southern California die cutting operations take advantage of cross-border savings, with production or storage often found in Northern Mexico and Baja California, specifically. While numerous companies use these services, there are some benefits to working with a die cutting vendor solely based in California.

| Aspect | Colvin-Friedman (California-only) | Maquiladora-Based Die Cutters |

|---|---|---|

| Proximity and Turnaround Time | Being based in California allows for same-day shipments within LA and rapid delivery throughout the state, ensuring fast turnaround. | Parts must be transported across the U.S.-Mexico border, adding time due to customs processing, which can cause unexpected delays. |

| Communication | Operates in the same time zone as LA clients, ensuring immediate responses and real-time collaboration without language barriers. | Potential language differences can slow down problem-solving and project adjustments. |

| Technological Expertise | Uses advanced rotary and flatbed die-cutting technologies suited for high-precision industries like aerospace and medical. | Some maquiladoras rely on older equipment and may not offer the same precision or material versatility. |

| Customization Flexibility | Provides on-the-fly adjustments for prototypes, design tweaks, and small production runs without logistical hurdles. | Custom orders often take longer due to production occurring off-site, requiring additional lead time for changes. |

| Sustainability | Local production reduces carbon emissions from international shipping and aligns with California’s strict environmental standards. | While closer than overseas alternatives, cross-border transportation still increases emissions and requires additional logistics. |

| Regulatory Compliance | Fully compliant with U.S. and California regulations, ensuring seamless quality control and legal compliance. | Navigating both U.S. and Mexican regulations can introduce compliance risks, such as unexpected duties, tariffs, or inconsistencies in quality standards. |

Or call Josh at (707) 769-4488

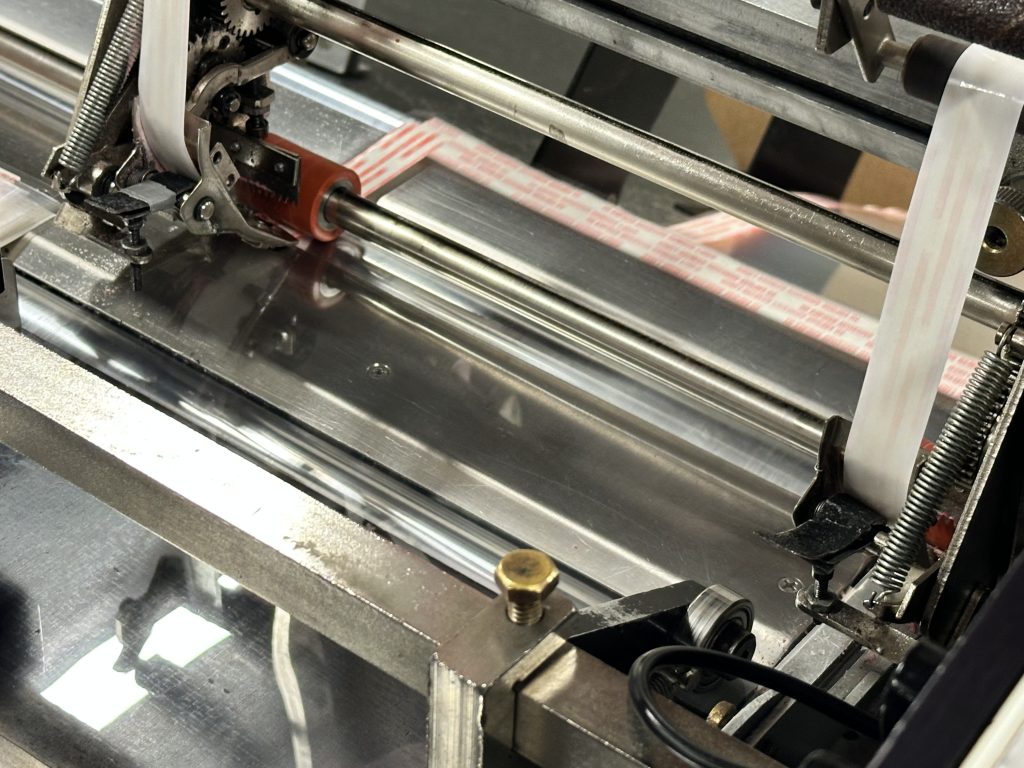

Our rotary die cutting process delivers precise cuts within tolerances as tight as 0.015 inches, making it ideal for intricate designs. This level of precision is especially beneficial for industries such as medical devices and electronics, where accuracy is essential. Our production can scale with yours, with production rates up to 40,000 per hour.

Flatbed die cutting enables the processing of more rigid and thicker materials, accommodating up to 0.5 inches in thickness. This technique, which includes steel rule die cutting, is well-suited for applications in aerospace. Steel rule die cutting offers a budget-friendly approach for low to mid-volume production runs, allowing for detailed cuts without excessive tooling expenses.

For adhesive-backed components, we offer kiss cutting, which allows the top layer of material to be cut into custom shapes while preserving the adhesive backing. This process is commonly used for gaskets, labels, and stickers, particularly in consumer goods and electronics. Kiss cutting ensures that components are easy to peel and apply, streamlining the final assembly process.

At Colvin-Friedman, we work with a variety of materials, including foams, rubbers, plastics, specialty films, and adhesive tapes. Our expertise allows us to recommend the best materials for each application, ensuring the final product meets functional and cost considerations. Whether the goal is thermal resistance, electrical insulation, or specific adhesive properties, we help identify the most suitable material for your needs.

High-quality die-cut components should integrate smoothly into production workflows. Our team not only offers post-cutting customization and assembly but also provides compatibility with most inventory management systems. This ensures reduced material waste and supports lean manufacturing processes, allowing us to function as a seamless extension of your supply chain.

Colvin-Friedman has been serving manufacturers throughout California and the world for more than 75 years. From our start at the dawn of the Electronics Age, we have focused on providing scalable die cutting of parts with intricate designs across material types. It is this combination of breadth and depth of experience that appeals to many L.A.-based companies, from fashion to high-tech industrial and beyond.

If you already have a design for a component, package insert or other part you would like a specific quote for, you can use our short form for the fastest response. For more detailed questions, start the conversation with Vice President Josh Harrison at (707) 769-4488. We look forward to partnering with you.