From high-performance gaskets to custom-cut adhesives, Colvin-Friedman delivers die-cut components tailored to Vancouver’s aerospace, tech, and industrial sectors. With over 75 years of expertise, we provide scalable production, tight tolerances, and fast shipping—all with seamless cross-border logistics. Get U.S. quality with the reliability of a local partner.

| Industry | How We Meet Your Needs | What We Make for Vancouver Companies |

|---|---|---|

| Technology & Electronics | Tight-tolerance, precision die cutting for high-performance components. |

- EMI/RFI shielding - Custom gaskets & seals - Adhesive-backed components |

| Forestry & Industrial Equipment | Durable, wear-resistant components that withstand harsh operating conditions. |

- Heavy-duty gaskets - Wear-resistant pads - Custom filtration components |

| Construction | High-quality insulation, sealing, and protective materials for modern builds. |

- Acoustic & thermal insulation - Custom gaskets & weather stripping - Vapor barriers |

| Marine | Marine-grade materials cut to exact specifications for maximum durability. |

- Seals & gaskets for extreme conditions - Anti-vibration pads - Thermal insulation for engine compartments |

| Aerospace & Automotive | Lightweight, high-tolerance die-cut components that meet strict performance and safety standards. |

- Precision-cut composites - Thermal & acoustic insulation - Adhesive-backed films |

Or call Josh at (707) 769-4488

| Compliance with North American Manufacturing Standards |

|---|

| For industries with strict material or quality standards—like defense, automotive, and medical devices—sourcing from a U.S. supplier ensures compliance with both Canadian and American regulations. Offshore suppliers often struggle with consistency, while local options may lack the technology or scale to meet demand. |

| Scalable Production for Growing B.C. Companies |

|---|

| Many B.C. businesses rely on small-scale or niche Canadian suppliers who may not have the capacity for high-volume orders or rapid scaling. Colvin-Friedman bridges the gap, offering low minimum order quantities but the ability to scale up production when needed—without the risks of working with an overseas manufacturer. |

| Higher Precision & Specialization Than Local Canadian Die Cutters |

|---|

| British Columbia has limited die-cutting providers, especially for specialized manufacturing sectors like aerospace, electronics, and medical devices. Many Canadian providers focus on basic die-cutting, while Colvin-Friedman offers tight tolerances, complex material handling, and scalable production that outperforms regional competitors. |

| Faster, More Reliable Shipping Than Overseas Suppliers |

|---|

| Colvin-Friedman’s location in Petaluma, CA, means shipments to Vancouver arrive in days, not weeks. Unlike offshore providers, there’s no waiting on container shipments, no supply chain bottlenecks, and no customs slowdowns that delay production. |

| Tariff-Free Trade with U.S. Under USMCA |

|---|

| British Columbia businesses can import die-cut components from Colvin-Friedman without tariffs, keeping pricing competitive with Canadian suppliers. Unlike offshore suppliers, there are no hidden duties or import headaches—just seamless cross-border trade. |

Or call Josh at (707) 769-4488

| Advantage | What It Means for Your Business |

|---|---|

| Tariff-Free Trade | USMCA ensures duty-free imports, keeping costs competitive. |

| Fast, Reliable Shipping | West Coast proximity means deliveries arrive in days, not weeks. |

| More Capability Than Local Providers | Specialized die-cutting for aerospace, medical, and industrial sectors. |

| North American Compliance | Meets strict U.S. and Canadian regulations for quality and safety. |

| Scalable Production | Flexible order sizes—low minimums with high-volume capacity. |

Or call Josh at (707) 769-4488

Colvin-Friedman offers a comprehensive range of die-cutting services tailored to meet the diverse needs of manufacturers. Below is an overview of our key capabilities:

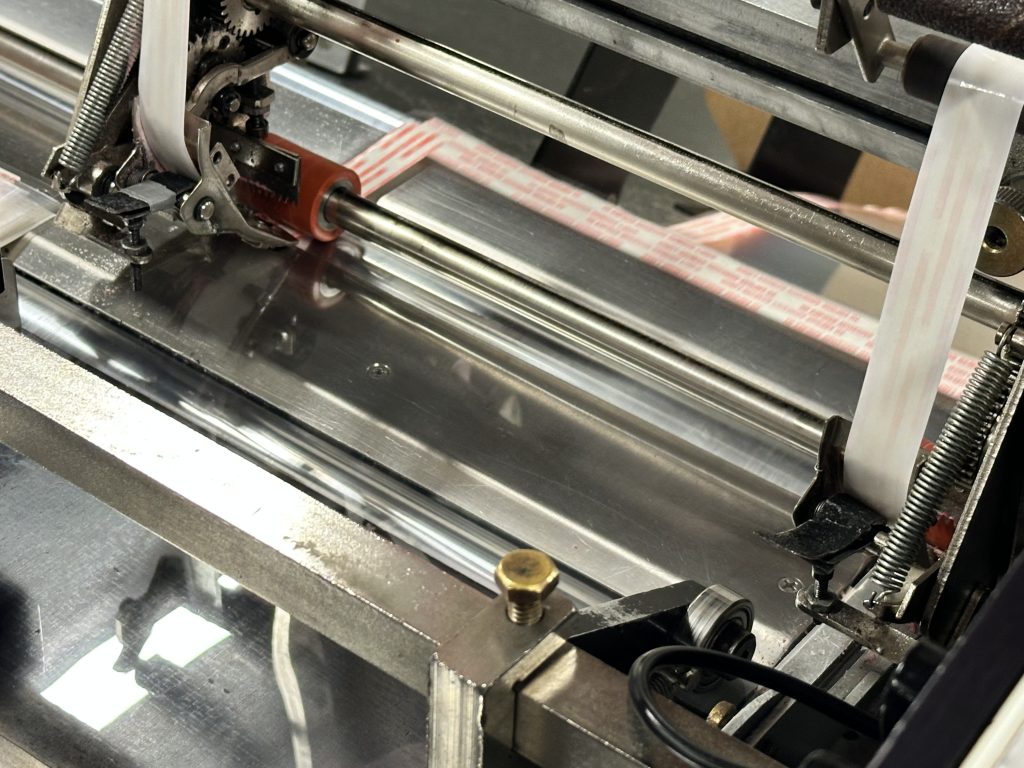

Our rotary die-cutting services are designed for high-volume production with exceptional precision. We can handle materials up to 16 inches in width and 0.015 inches in thickness, achieving tolerances as tight as ±0.005 inches. This process is ideal for producing intricate components at rates up to 40,000 units per hour. Common materials include paper, foam, foil, plastics, composites, and adhesives.

Our flatbed die-cutting services accommodate materials up to 40 inches wide and 0.5 inches thick, with tolerances of ±0.010 inches. This method is suitable for both low and high-volume runs, offering flexibility for various project requirements based on the thickness and hardness of the material used. We work with a wide range of materials, including plastics, foams, rubbers, tapes, fiber, fabric, paper, and pressure-sensitive adhesives (PSAs).

Steel rule die cutting is a cost-effective solution for cutting a variety of materials with precision. This technique is particularly advantageous for prototypes and short to medium production runs, allowing for detailed cuts without significant tooling expenses. Materials commonly processed include plastics, foams, rubbers, and more.

For applications requiring exacting standards, our precision die-cutting services deliver components with the highest accuracy. We utilize advanced equipment to produce parts that meet stringent specifications, essential for industries such as medical devices and electronics. Materials include thin-gauge films, sheet plastics, and other specialized substrates.

Our kiss-cutting services are ideal for creating adhesive-backed components, such as labels, gaskets, and stickers. This process ensures the top layer is cut to the desired shape while leaving the backing intact, facilitating easy application. Materials suitable for kiss cutting include tapes, foams, and various adhesives.

Beyond die cutting, we offer comprehensive converting services, including laminating, slitting, and rewinding. These capabilities allow us to provide finished products that meet your exact specifications, ready for immediate use or further processing.

To support your supply chain needs, we provide packaging services tailored to your requirements, ensuring products are protected and presentation-ready. Additionally, our stocking programs integrate with your inventory management systems, offering solutions such as just-in-time delivery and same-day shipping to streamline your operations.

Understanding the importance of efficient supply chain management, we offer services that integrate seamlessly with your inventory systems. Our capabilities include just-in-time delivery, Kanban systems, and same-day shipping for blanket purchase orders, minimizing lead times and reducing inventory costs.

Our extensive experience encompasses working with a broad spectrum of materials, including:

With over 75 years of experience, Colvin-Friedman is dedicated to delivering high-quality die-cut solutions tailored to your needs. Whether you have a specific design in mind or require guidance on material selection and process optimization, our team is here to assist you.

For a prompt quote, please fill out our request form. For more detailed inquiries or to discuss your project requirements, contact Vice President Josh Rodman at (707) 769-4488. We look forward to partnering with you to achieve your manufacturing goals.

Or call Josh at (707) 769-4488