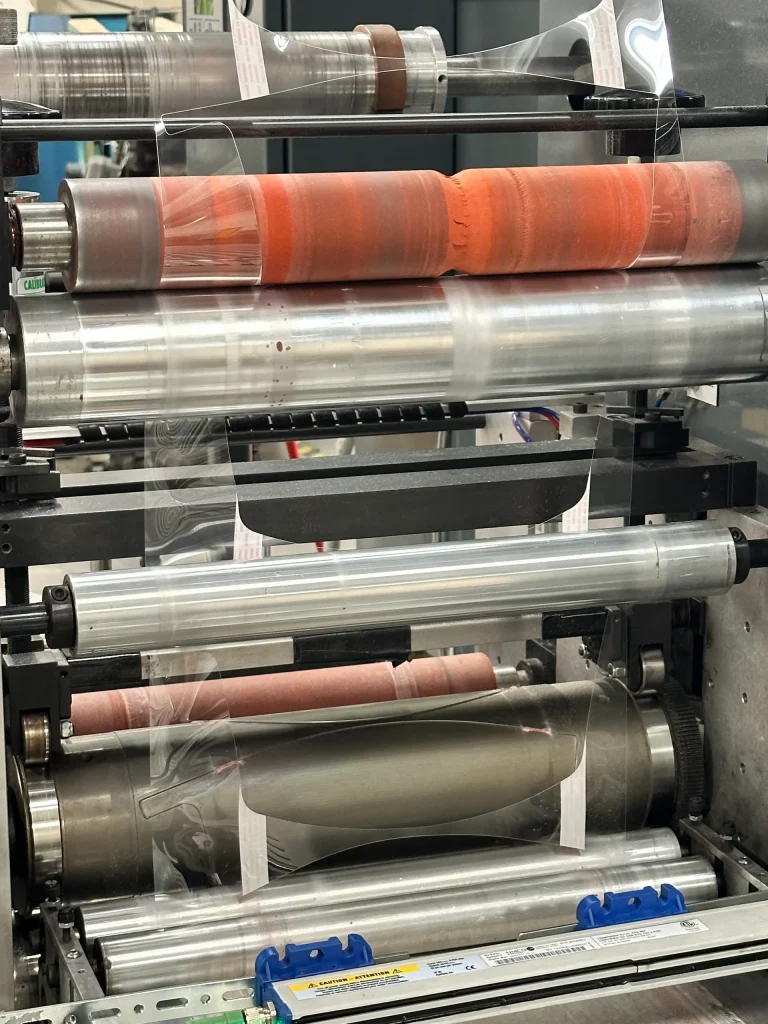

Colvin Friedman is one of the oldest and most experienced die-cutting companies in the United States. Since our founding we have been known for quality rotary die-cut products made to exceed our customers’ expectations. See the information below for our rotary die-cutting capabilities.

Or call Josh at (707) 769-4488

We can rotary die-cut products generally that fit within the following specifications. Depending on the design and material we can accommodate some products outside of the specifications. If your design does not work with the specifications we may recommend flatbed die cutting to accommodate.

Maximum Product Width

Maximum Product Thickness

Tolerance Level

Maximum Production Capacity

Average Lead Time

16 inches we can slit down larger jumbos

.015 inches however there is flexibility with different materials

Can get down to ±0.005 inches

40,000 units/hour (size dependent)

3 weeks

If you are unsure whether your product or component can be rotary die cut consider contacting our Vice President Josh Rodman for more information. Also if you are changing your rotary die-cutting provider and wish to understand our pricing and see examples of our work product Josh will provide any needed information.

Or call Josh at (707) 769-4488

We can generally rotary die-cut any material for your products or components if they fit within the specifications listed above. Commonly we use these materials:

If you are unsure which material to use for your product or component we will advise which will perform the best for your use case. There are a few important considerations when choosing a material to be rotary die cut:

We are happy to assist in material selection and provide a pros/cons list for each. Contact us below to begin the process of material selection and quoting.

Or call Josh at (707) 769-4488

Our rotary die-cutting experience and expertise speak for themselves. We have partnered with companies all over the USA & the world to produce the following:

Many people are unsure whether rotary die-cutting is the right solution for their product or component. Use the following checklist to determine if rotary die cutting will be a fit for your product.

If your product steps outside of these you may consider flatbed die cutting. We also offer flatbed die cutting and can help you choose between the two.

Suitable for high-volume orders providing economies of scale

Consistently high precision ideal for complex and detailed designs

Efficient material utilization reducing waste and costs

Faster turnaround times for large orders

Higher setup costs making it less economical for small batches

Limited to materials in roll form reducing material options

Changes in project scope or design can be costly and complex to implement

Typically requires a long-term commitment due to setup investment

More adaptable for low to medium volume without high setup costs

Capable of handling a wider variety of materials and thicknesses

Flexibility in setup allows for customization and changes in design

Often more cost-effective for short runs and prototypes

Slower production rates can lead to longer turnaround times

Higher material waste due to spacing between cuts affecting cost

Operation can increase labor costs due to material handling

Less suitable for very high-volume jobs due to slower speeds

If you are unsure which option will work best for your product/component and your desired production run size we are happy to assist. Reach out below for a free quote along with guidance on choosing a type of die cutting.

Or call Josh at (707) 769-4488

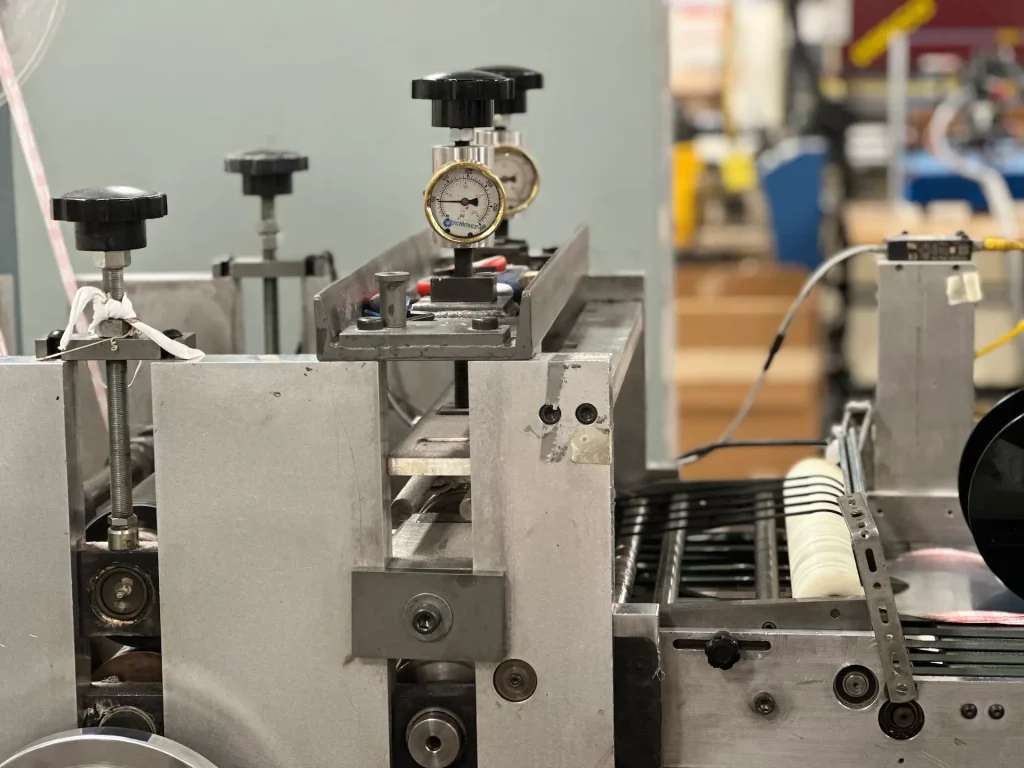

Planning and Pre-Production

Die Construction

Die Construction

High Quality Materials

Testing and Adjustments

CAD

Optimize Die Geometry

Experienced Toolers

Quality Steel for Dies

Milling and Heat Treatment

Produce Test Products

Precise Calibrations

Sample Tests

Optimized Systems

Material Guides and Rollers

Source best materials available for premium components

Test and adjust die design if necessary for peak quality

Utilize Computer Assisted Design (CAD) software to precisely design die

Design for optimal bevel angles, to avoid material build up and reach peak efficiency

Guarantee Top Quality Dies are created by experts

Dies are created with high grade steel for clean cuts and maximum durability

Help ensure sharp and durable edges for the die

Initial products are evaluated to ensure die’s quality before productio

Machines are set to client’s specific requirements

Integrated to ensure dimensions and tolerances remain up to standard throughout production

Use SCADA and PLC systems to enhance and automate the cutting process

Keep material fed smoothly through machine, avoiding friction and drag

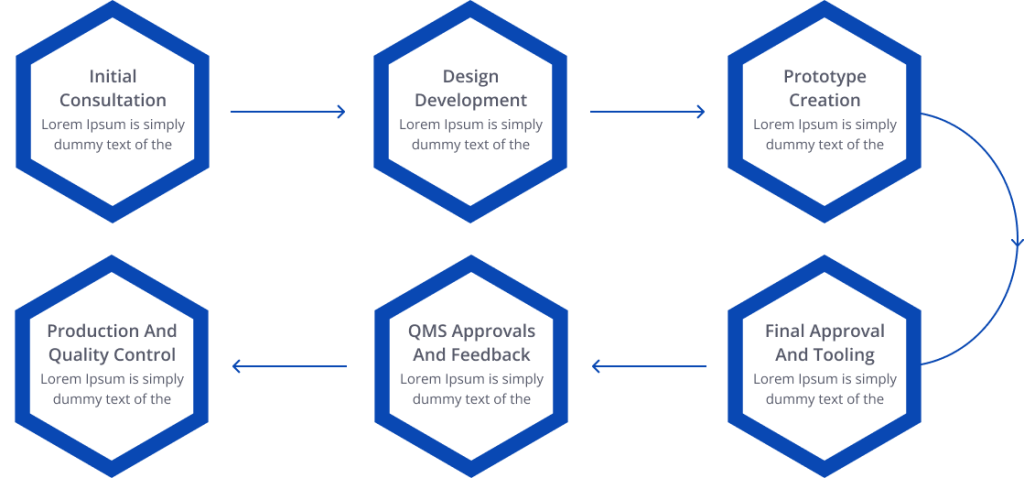

At the core of our process is quality. We ensure each product from the first to the last is within your specifications and will work perfectly for your use case. Below we’ve included a diagram explaining our process to ensure all products are made to your specifications and with the utmost quality.

01

During the initial consultation, we examine your product specifications and determine important specifications such as the type of die cutting that should be used, the material, finishing requirements, and tolerance requirements. If a prototype is needed we will aid in creating it for you. Once the final design is settled on, we create several test products to ensure the design is perfect before heading into production.

02

Before the production process, we perform tolerance level tests, overall dimension tests, and fit and function tests to test the quality of the design. If the product does not pass the tests with flying colors, we will assist in design refinement to ensure a smoother manufacturing process. At this stage, the customer may perform their own tests and provide feedback. We can create multiple iterations of the product to enhance quality and functionality.

03

Before production, the product is put through our full QMS to ensure the product will work perfectly for the customer once produced. We work quickly to get our machines equipped to produce the order. A small-scale production run is done as a final fail-safe before the full production run. Any adjustments can be made before the full production run.

To request a quote or ask any questions you may have, please click the button below to visit our request a quote page or call Josh at (707) 769-4488.

Or call Josh at (707) 769-4488

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

1311 Commerce Street • Petaluma, CA 94954

copyright © 2025 Colvin Friedman Company. All Right Reserved.