A Complete Guide to the Die Cutting Process

Die cutting is a manufacturing process that involves cutting materials into specific shapes and sizes with precision and consistency. This process is achieved by using a cutting tool called a die made of steel and designed to match the exact specifications of the part or component being created. Die cutting is a popular method in the manufacturing industry for creating parts, gaskets, and other components with high precision and consistency.

Benefits of Using Solid Dies Over Flexible Die

Solid dies have many advantages and disadvantages, so you should never use this die type for all die-cutting applications. A solid die is relatively popular in manufacturing, but some drawbacks still prevent it from being used in more die-cutting applications. When comparing a solid die to its counterpart (flexible die), it is always seen as better for a wide range of manufacturing applications. For instance, solid dies can easily cut thick and abrasive materials with multi-layer construction. Solid dies do not fault with high and long-run production: they are solid, strong, and reliable in these situations. The best die cutting CA has to offer provides custom die cutting solutions with both flexible and solid die cutting options.

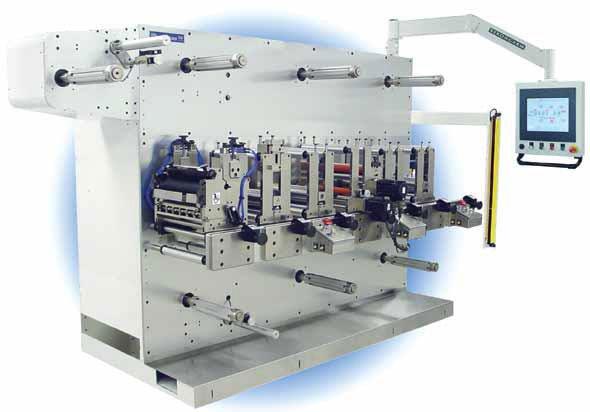

Rotary Die Cutting Services & Thermal Masking Solutions

The realm of rotary die cutting holds significant importance across many industries, from automotive and electronics to healthcare and packaging. This technology’s exceptional ability to fabricate intricate shapes and designs with precision and high-speed production has made it an indispensable solution for manufacturers.

Rotary Die Cutting: Essential for Efficient Thermal Barrier Tape Implementation

Rotary die cutting is vital in crafting effective thermal barrier tape solutions, protecting equipment and staff from cold-induced damages in sectors where low temperatures present challenges. When using rotary die cutting, thermal barrier tapes can be meticulously customized to fit various surfaces, ensuring optimal insulation and defense.

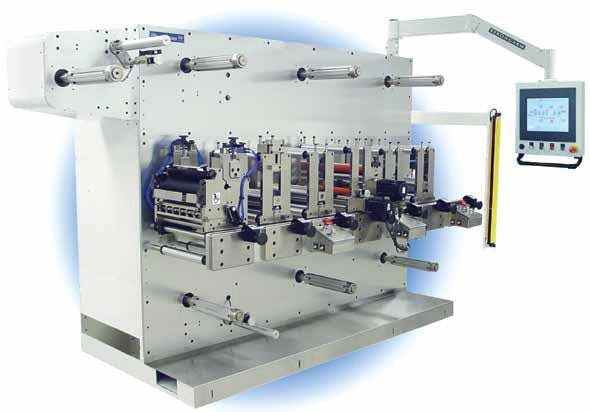

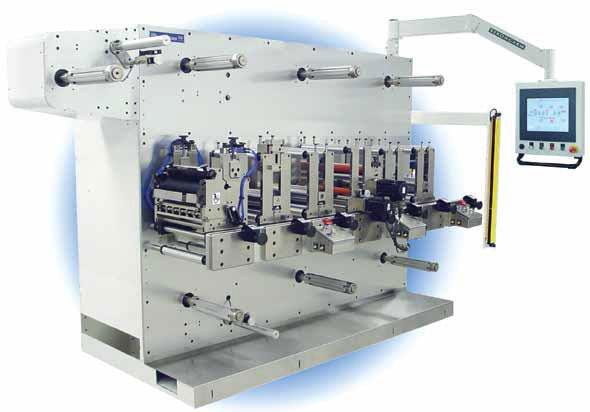

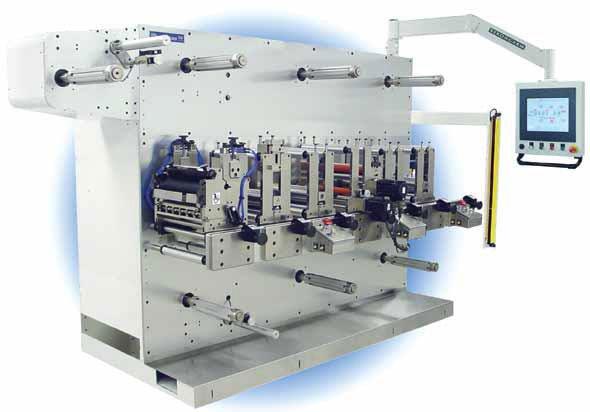

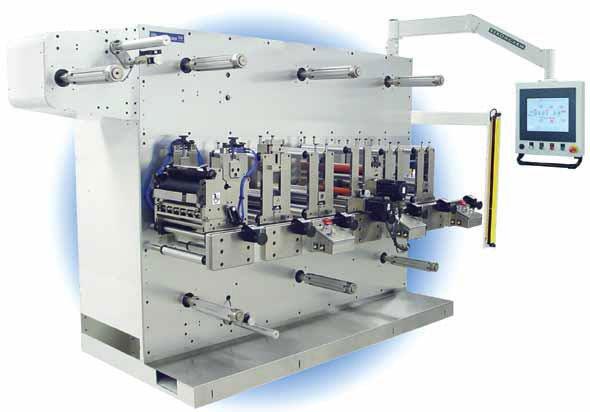

The Main Components of a Commercial Die Cutting Service

A commercial die cutting service typically consists of several vital components that work together to produce precise and accurate cuts on a wide range of materials. These components include:

How does Rotary Die Cutting help to Save Lives?

When they hear the term die cutting, many individuals immediately associate it with creating pursuits like scrapbooking. Any person can buy an at-home die cutting machine to make beautiful cutouts for a relatively small price. Graphic and interior designers can use these printers for their jobs. Although this is a popular form of die cutting, it is the least used form of die cutting. More commonly, the manufacturing process is used on a global, commercial scale that requires large machines, ample materials, and long-run times.

Colvin-Friedman’s Expertise in Custom Die Cut Parts

Colvin-Friedman has established itself as a leader in plastic die cutting since 1988. Our expertise in die cutting plastic has been a cornerstone of our operations, enabling us to provide high-quality, precision-engineered plastic parts to various industries.

Kiss Cutting Plastic with Custom Die Cutting Services

Kiss cutting is a specialized die cutting process that pierces through the upper layers of a material while leaving the backing layer intact. This technique is often used in manufacturing labels, stickers, and other adhesive-backed products, where the precision of the cut is paramount. The process involves using digital die cutting machines that accurately control the pressure required to cut, creating a “crack and peel” surface for easy liner removal. This method is highly valued for its efficiency and precision, particularly in the timely assembly of parts and components in various manufacturing operations. The best die cutting in CA offers a multitude of options for kiss cutting and more.

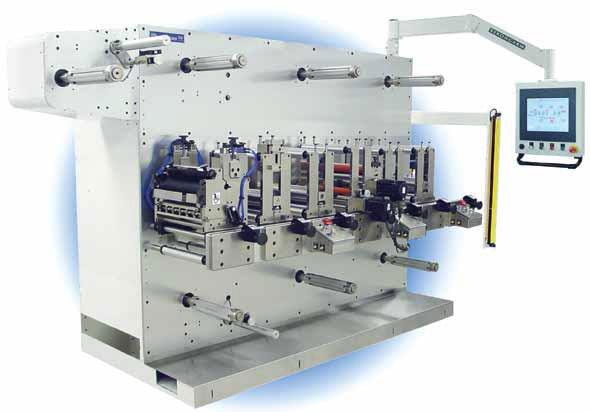

Preparation and Processing for Custom Rotary Die Cutting

Rotary die cutting is a sophisticated manufacturing process widely used in various industries to cut, shape, and create precise parts. This process involves several critical stages, from selecting appropriate materials to processing them correctly for optimal results. We will delve into the preparation and processing aspects of rotary die cutting, focusing on materials like Nomex, Vulcanized Fiber, and various paper products.

Rotary Die Cutting PETG Plastic: Die Cutting Services CA

When choosing materials for manufacturing processes like rotary die cutting, it’s essential to look beyond the inherent characteristics of the materials themselves. Understanding how a material interacts with a specific manufacturing process can significantly impact the efficiency, cost-effectiveness, and quality of the final product. Different materials respond uniquely to processes like cutting, forming, and finishing, making the choice of material a critical decision in the production line. Polyethylene Terephthalate with a Glycol Modifier (PETG) is a versatile thermoplastic, increasingly popular in various industries. Its properties make it particularly suitable for rotary die cutting, a common and efficient method for mass-producing precision parts.