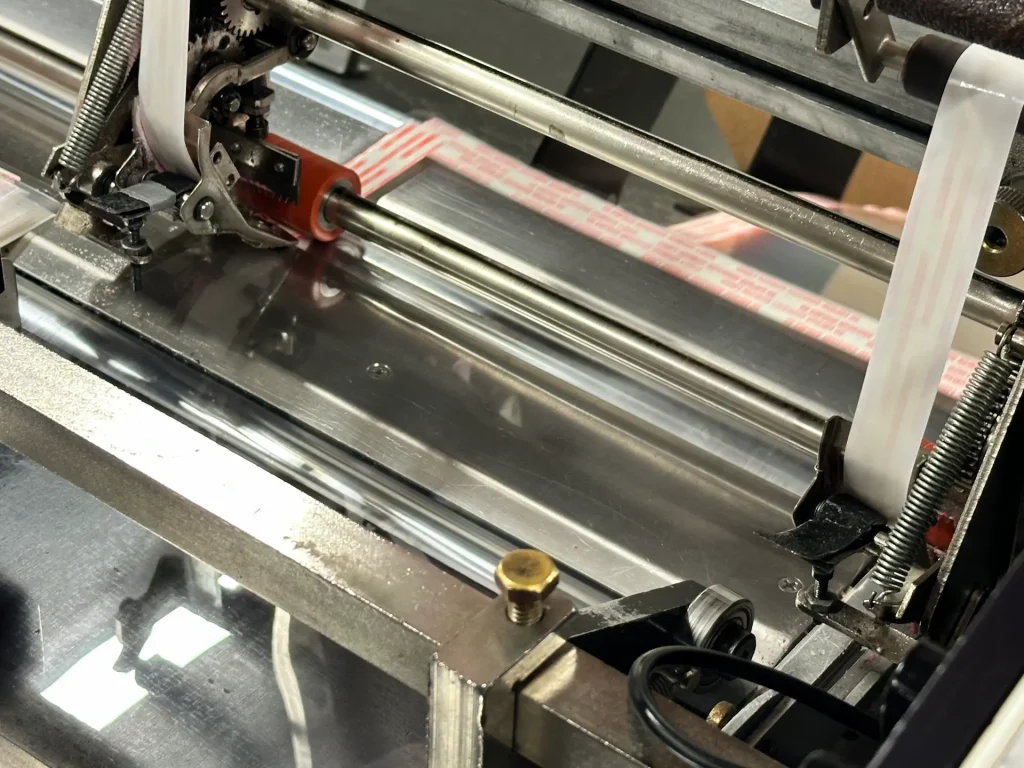

This page compiles information on Colvin Friedman’s die-cutting capabilities and process. As shown below we are able to cut a wide variety of products and materials, all roughly within the specifications outlined.

Rotary and Flatbed Die cutting are the two most commonly performed services we offer. Both services allow for a great amount of flexibility, as outlined in the table below.

Maximum Product Width

Maximum Product Thickness

Tolerance Level

Maximum Production Capacity

Average Lead Time

Common Materials

Die Types

Secondary Capabilities

Average Initial Tooling Cost

Average Setup Time

16 inches, we can slit down larger jumbos

.015 inches, however, there is flexibility with different materials

Can get down to ±0.005 inches

40,000 units/hour (size dependent)

3 weeks

Paper, Plastics, Film, Foil, Laminates, Adhesives

Flexible Dies, Solid Rotary Dies

Laminating, Slitting, Kiss Cutting, Embossing, Printing, Sheeting, Scoring

$500-2000

1 hour

40 inches

.5 inches, material dependent

±0.010, material dependent

2,000 – 4,000 parts/hour (size dependent)

3 weeks

Plastic, Rubber, Foam, Composites, Certain Metals

Steel Rule Dies, Male and Female Dies

Embossing, Debossing, Kiss Cutting, Forming, Punching, Shearing, Notching, Scoring

$100-500

20 minutes

Or call Josh at (707) 769-4488

Below we have listed out the specific services we offer under the categories of rotary die cutting, flatbed die cutting, and various converting services.

Or call Josh at (707) 769-4488

As one of the oldest Die cutting companies in the United States, Colvin Friedman is no stranger to changing client needs and to the dynamic nature of supply and demand. That’s why we’ve paired our large production capacity with a small shop sensibility. Every production is overseen by our vice president, Josh Rodman, who is never more than a phone call away from any client.

Throughout our time in business we’ve built our systems to respond and adapt to the market as it is. Having produced over a million face shields during the Covid-19 pandemic, and offering unique, technology driven stocking services, we’re always prepared to meet your needs.

01

02

03

04

05

Our primary speciality is plastics like PETG and Polyethylene, but we additionally cut thousands of units of paper, adhesive, and foam products.

Average productions will require 3 weeks of lead time.

Customers interested in a more in depth partnership and in need of frequent inventory restocking may consider Colvin Friedman’s stocking services to immediately have their inventory restocked.

We can directly integrate with a majority of inventory management systems, including Kanban, End to End, and JIT.

We frequently produce high volume orders for large companies. During the COVID-19 pandemic, Colvin Friedman was able to cut 1 million face shields over a three-month period.

Depending on the nature of your project, we can cut up to 40,000 units per hour.