We’ve been serving corporate customers with custom plastic die cutting services for more than 75 years. Our combination of individual experience and organizational expertise enables us to provide the highest quality product within fair timelines. Plastics can vary greatly, however, so it is imperative to use the right process, die material and tooling to assure the final components meet the required specifications.

Or call Josh at (707) 769-4488

While there are broadly two categories of plastics, the actual number of variants is in the dozens. They vary based on chemical properties, such as hardness, resistance to impacts or abrasions, chemical and heat protection among several other factors. We’ve provided a brief overview of some of the most common types, split between thermoplastics which can be reheated and reformed, and thermoset plastics which cannot.

PETG (Polyethylene Terephthalate Glycol)

Polyethylene (PE)

PVC (Polyvinyl Chloride)

Polycarbonate (PC)

ABS (Acrylonitrile Butadiene Styrene)

Polypropylene (PP)

Acrylic (PMMA)

Clear, tough, good chemical resistance

Flexible, chemical resistant, low cost

Versatile, durable, flame-retardant

High impact strength, heat resistant, transparent

Tough, rigid, good dimensional stability

Lightweight, good fatigue resistance, chemical resistant

Optical clarity, UV resistant, rigid

Face shields, packaging, signage

Packaging films, gaskets, containers

Medical tubing, credit cards, wire insulation

Safety glasses, automotive parts, electronic components

Electronic housings, automotive trim, protective headgear

Hinges, living hinges, food containers

Display panels, lenses, light guides

Phenolic

Epoxy

Polyurethane

Silicone

Melamine

Heat resistant, electrical insulator, dimensionally stable

Strong adhesion, chemical resistant, good electrical properties

Flexible, abrasion resistant, impact resistant

Heat resistant, flexible at low temperatures, electrically insulating

Hard, heat resistant, good electrical properties

Electrical components, automotive parts, circuit boards

Adhesives, coatings, electronic encapsulation

Gaskets, seals, cushioning components

Gaskets, seals, medical implants

Kitchenware, decorative laminates, electrical switches

Or call Josh at (707) 769-4488

When working with a die cutting company, it’s important to ensure that someone, either you or your supplier, has the experience and expertise to follow each of the following steps to ensure that your custom plastic die cutting application comes out correctly, on budget and within schedule. They also happen to follow the steps that Colvin-Friedman takes with each of our clients to ensure that projects are successful within tight tolerances or timeframes:

As noted above, choosing the right plastic for the application is a key component in ensuring that the parts meet all required specifications for stress, resistance and other measures. An experienced custom plastic die cutting company can handle issues like PVC’s off-gassing or polyethylene’s low melting point. In order to make it simpler to review plastic types, we’ve included a selector enabling you to choose the traits most important for your application and receive some plastic options to consider.

| The Role of Temperature in Creasing Certain Materials |

|---|

| Plastics, elastomers, and composites can respond differently at different temperatures. Cold creasing can lead to cracking, while heated creasing (sometimes called heat-assisted creasing) can make certain materials more pliable for permanent fold structures. |

| Colvin-Friedman maintains temperature and humidity checks within production facilities to maximize creasing and scoring efficiency. |

DFM, or designing for manufacturing, is one of the first elements of quality control in a project. It’s where the design is simulated through either experience and rubrics or actual simulations to ensure that parts will be able to be completed per their design. To take just one example, the distance between holes or holes and edges should be at least 1.5 times material thickness for most plastics. Another would be to consider grain direction to reduce splitting and cracking risks.

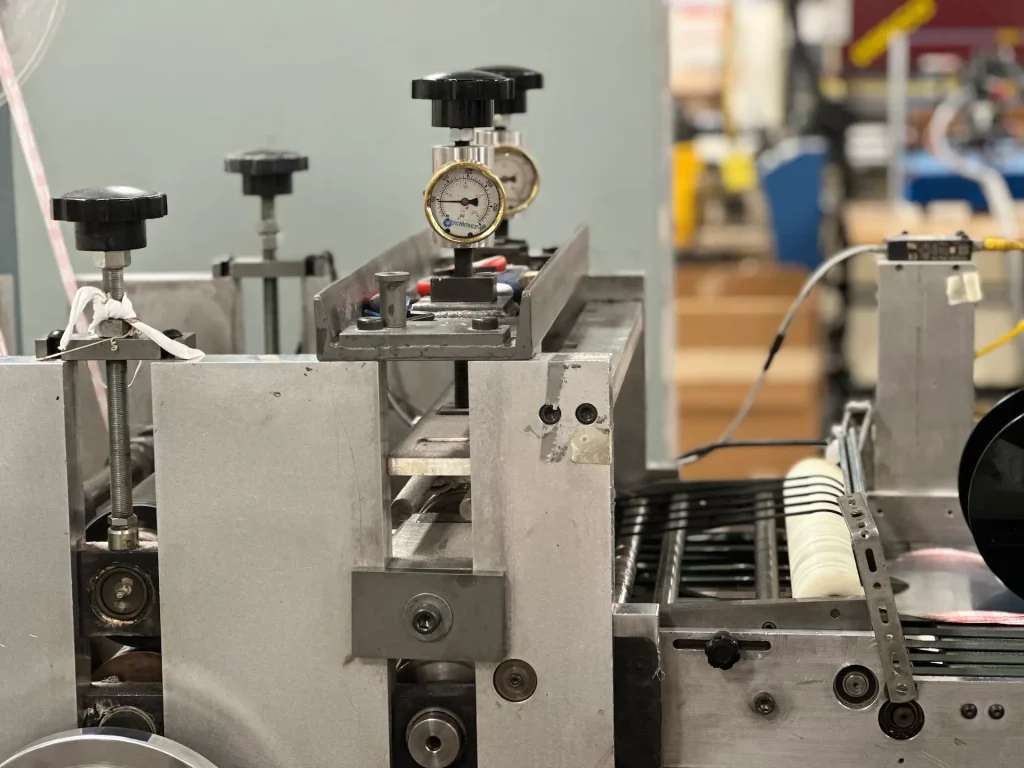

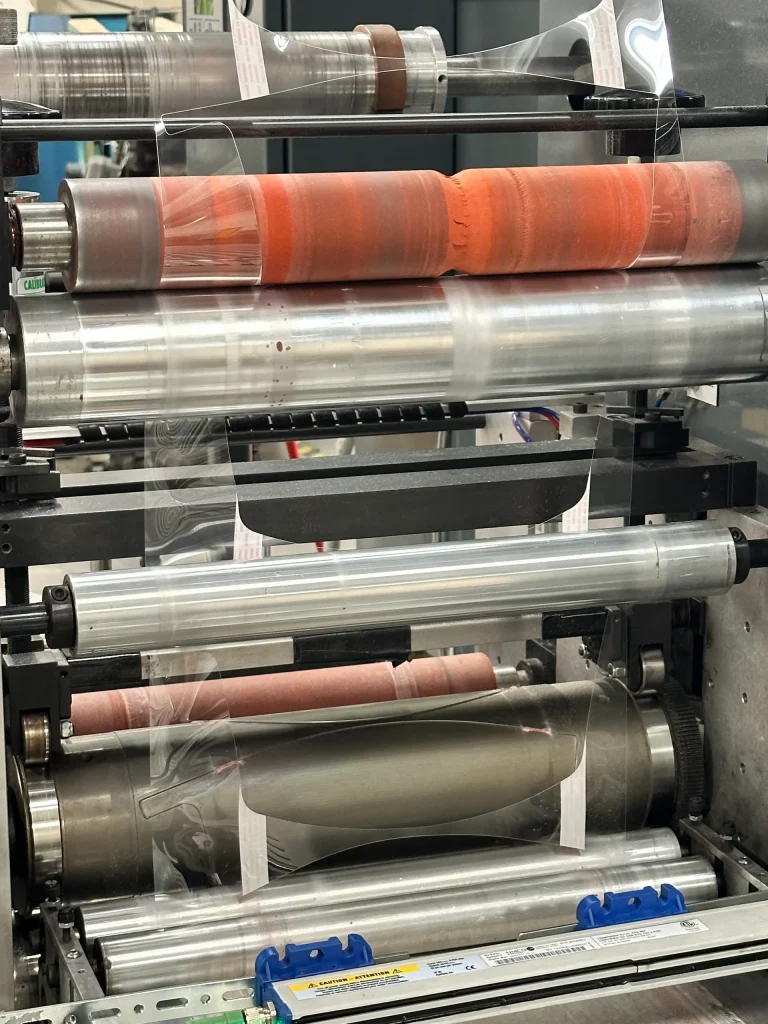

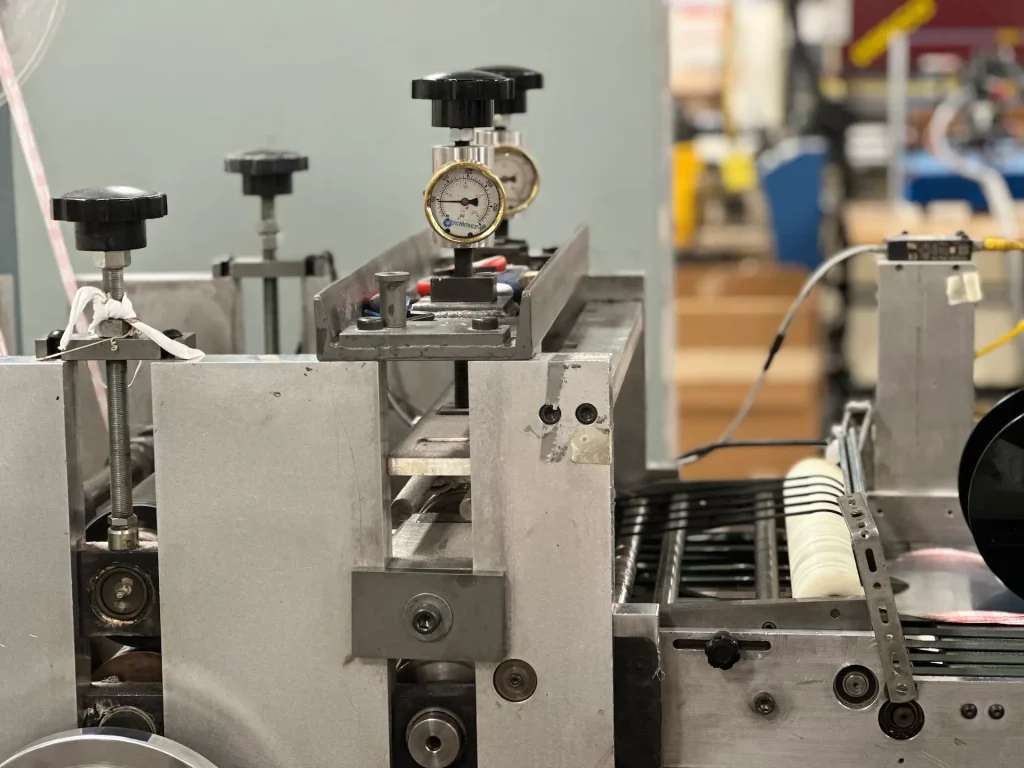

Since each customer’s product has a unique set of specifications it is imperative to ensure that the tooling perfectly matches the design characteristics, volume requirements, and budget. For example, in general, thinner and less rigid plastics can be cut using rotary dies or chem etch dies on mag cylinders. Thicker plastics may require a steel rule, matched metal or forged die to ensure the product will conform with all design and production parameters.

Maintaining consistent conditions and processes will be the key to any successful custom plastic die cutting project. Experienced technicians, engineers and QA personnel monitor every aspect of production during the manufacturing process to assure quality finished goods are produced. We have found that the key to increased productivity is a constant focus on quality control during the work in process phase.

While monitoring of the processes is critical, so too are the outcomes. At Colvin-Friedman, our quality control staff utilize modern statistical sampling plans from the inbound raw material phase through to the finished goods shipment. We maintain lot traceability for each and every production run large or small. Our team develops a quality map for every customer’s product to make sure your product is made correctly the first time and every time.

Or call Josh at (707) 769-4488

Die cutting thin-gauge plastics is a highly efficient way to produce precise, repeatable parts — but optimal results start with design. At Colvin-Friedman, we regularly work with engineers during the prototyping and tooling phase to refine part geometry for better material yield, tighter tolerances, and cleaner edges.

Here are several considerations when designing components for die cutting from plastic sheet or roll stock:

Collaboration during early-stage design allows us to flag potential issues before tooling is committed, saving time and cost while improving part performance and consistency.

Or call Josh at (707) 769-4488

Below are some of the best practices we’ve developed that help mitigate some of the common and less common issues with custom plastic die cutting.

Static can cause materials to misalign or stick together during the production process, so active elimination systems like ionizing bars along the production lines are the first line of defense. In some cases, special additives may be required for either the plastic in use or as a coating for the dies to ensure static is kept at bay throughout the process, along with maintaining consistent relative humidity.

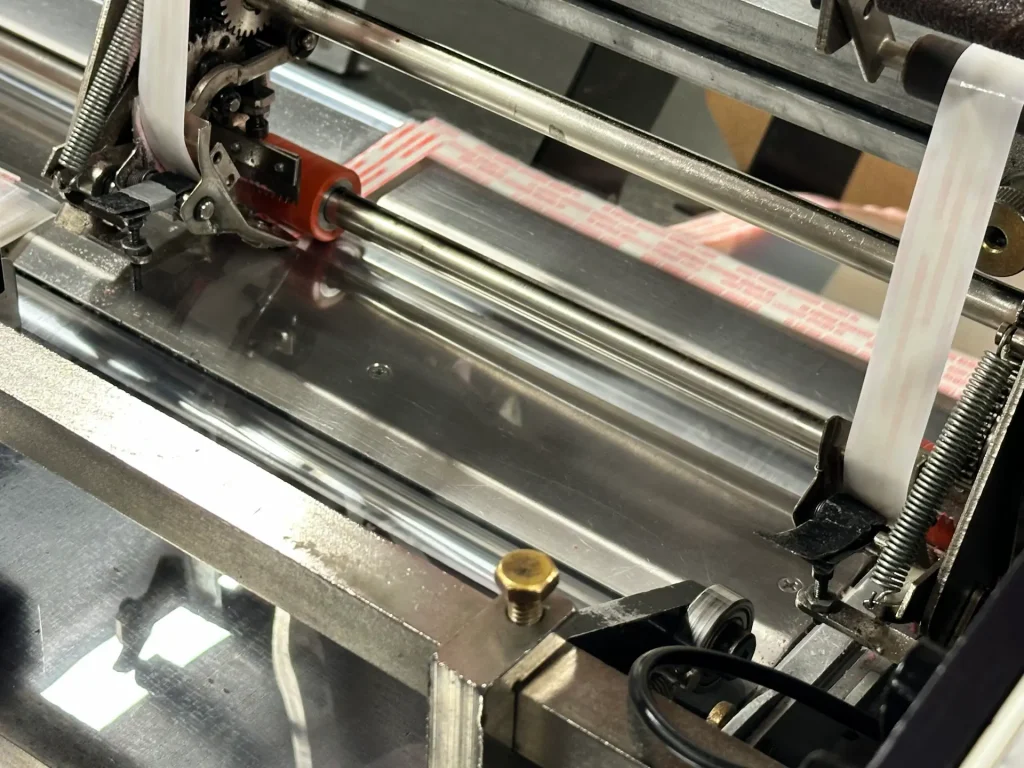

While the most common reason for edge inconsistency is a lack of die maintenance, other factors come into play as well. Fibrous plastics that have a specific grain can be cut using shear action or a two-stage cutting process. Experts will also be able to modify the speeds and pressures involved to maximize efficiency without reducing quality.

Temperature control is critical in ensuring custom plastic die cutting success. Experienced die cutters will acclimate the materials to the operating conditions prior to a run and consistently monitor both temperature and relative humidity levels within the facility.

An experienced die cutter will carefully monitor production run speeds to maintain consistent temperature ranges as well as pause cycles. For certain low-melt plastics, different die coatings may be required.

During the design phase, check that there are minimal stress points and ensure that the die cutter’s die-making accounts for potential brittleness. In some cases, heating the material beforehand or annealing afterwards can minimize the effect.

Ensure the die cutter uses pressure control systems, including feedback loops along with floating plates, to adapt to minor variations. Verify that the die cutter has a schedule in place for regular die maintenance and replacement for larger orders.

Colvin-Friedman offers both flat-bed and rotary die cutting capabilities, allowing us to match each project with the most efficient and cost-effective production method. The choice often depends on factors like material thickness, part geometry, production volume, and tolerance requirements.

By offering both cutting methods in-house, we help clients transition from prototyping to full production without switching vendors. Our team evaluates your design, material, and production needs to recommend the best approach for cost and efficiency, whether you’re producing insulation spacers, protective overlays, tabbed liners, or layered plastic components.

At Colvin-Friedman, we support customers who need more than just prototypes. Our team delivers production-ready plastic components with the consistency, speed, and attention to detail that modern manufacturing demands.

We work with thin-gauge plastic materials up to 0.10 inches thick, including adhesive-backed sheets and multi-layer laminates. Whether you’re supplying material on rolls or as individual sheets, we adjust our process to meet your part requirements and production volume.

One example of this capability was a high-volume PPE order during the COVID-19 pandemic. We produced over one million die-cut face shield components on a tight timeline while maintaining quality and clear communication with the customer throughout the process. That same responsiveness and precision applies to everything we do, from protective overlays and insulation barriers to plastic gaskets and custom spacers.

With both rotary and flat-bed die cutting equipment in-house, we can accommodate short runs, full production, and future design changes without introducing delays or compromising quality. Many of our clients continue to work with us across multiple product cycles because they know we can scale production while keeping tolerances consistent.

If you need thin plastic components delivered on time and to spec, our team has the experience and process control to make it happen.

If you are looking for the expertise that comes with 70 years of custom die cutting experience, Colvin-Friedman is excited to provide you a complimentary quote on your project. We are able to advise on material selection, design considerations and remain in constant contact with you throughout the process before integrating with your inventory management system.

For more information, click the button below to request a quote or call our Vice President Josh at (707) 769-4488

If you would like more information about our custom die-cutting services, process, or product capabilities, please use the number below to call our Vice President, Josh Rodman. If you would like to receive a free project quote, click the button below.

Or call Josh at (707) 769-4488

We have been a leading provider of die cutting services for over 75 years. Trust us to provide the customer service of a small business with the capabilities of a large organization.

1311 Commerce Street • Petaluma, CA 94954

Copyright © 2025 Colvin Friedman Company. All Right Reserved.