With nearly 75 years of experience specializing in midwestern industries ranging from food services to medical devices, Colvin-Friedman has become a trusted name for die cutting services for manufacturers in the Midwest. We proudly offer a wide variety of die cutting services that range from rotary and flatbed die cutting to kiss cutting and packaging.

Family-owned and operated, we are committed to providing top quality. Our top-of-the-line machines can handle almost any job, no matter the material, shape, or run size – making us the preferred die cutting partner for all manufacturers across the Midwest, no matter the industry.

Colvin Friedman’s first hand experience spans multiple industries that drive the economy of the Midwest. Here are just a few:

Food Production

Heavy Machinery

Aerospace

Motor Vehicle Assembly

Medical Devices

We can create customized packaging tailored to any food product to help better protect the food and allow it to stay fresher for longer. Die cutting also helps to reduce waste by custom cutting the plastic packaging to fit the precise shape and size of each food product. Unique die-cut labels will also help with branding.

Our die cutting services can help create gaskets and seals that will fit perfectly within the machine’s design, ensuring top quality. We pride ourselves on our ability to mass produce identical parts quickly, which is ideal for the small parts needed in creating heavy machinery.

Custom cut components such as thermal management, vibration damping, and seals are crucial for the aerospace industry. Our highly precise and customized die-cutting services can help Midwest aerospace manufacturers create these parts in a highly efficient and timely manner.

Colvin Friedman can create everything from gaskets and seals to vibration dampeners, enhancing the efficiency and quality of the automotive systems. We’re also able to cut automotive-grade plastics that can be used for interior trims, engine bay insulations, and dashboard components.

We specialize in cutting the complex shapes often required in the medical industry. We’re able to cut adhesive materials to help create adhesive bandages, medical tapes, and even electrode pads for EKGs. We can also help cut fabrics that can be used for surgical drapes, disposable gowns, and even compression bandages.

Or call Josh at (707) 769-4488

With industry-leading technology, we can ensure top quality, precision and efficiency for manufacturers serving the Midwest.

Materials:Paper, Foam, Foil, Plastics, Composites, Fiberglass, Metallic Foil, Polyester Films, Rubber, Adhesives, Fabric, Felt, Silicone, and Nonwovens

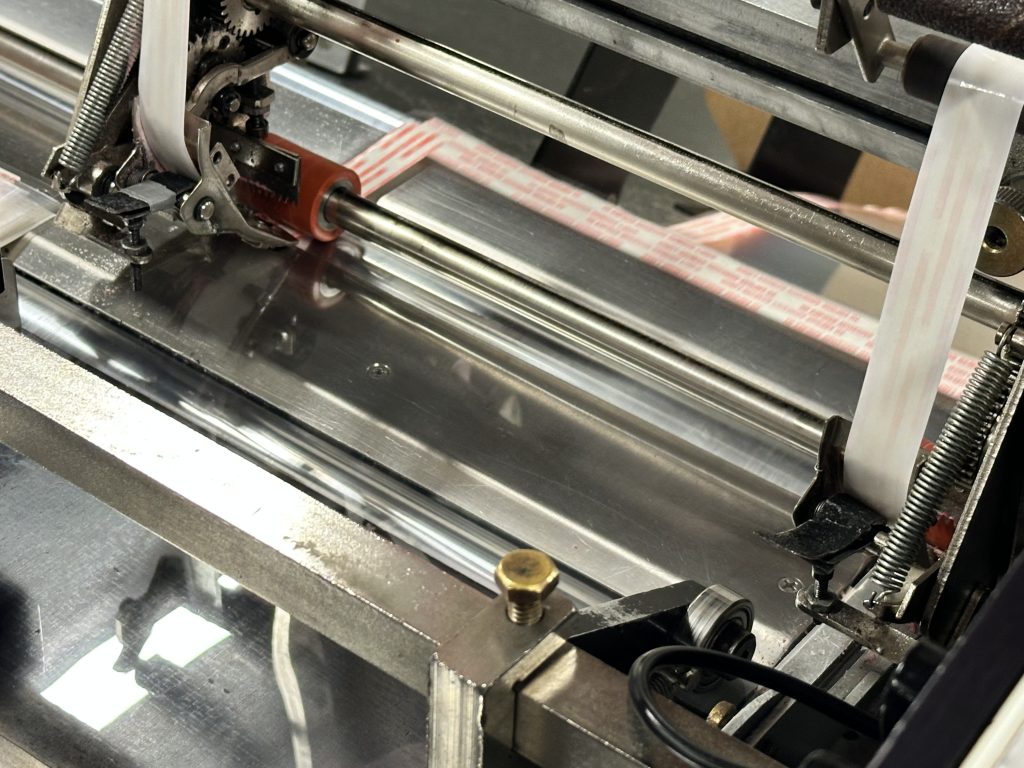

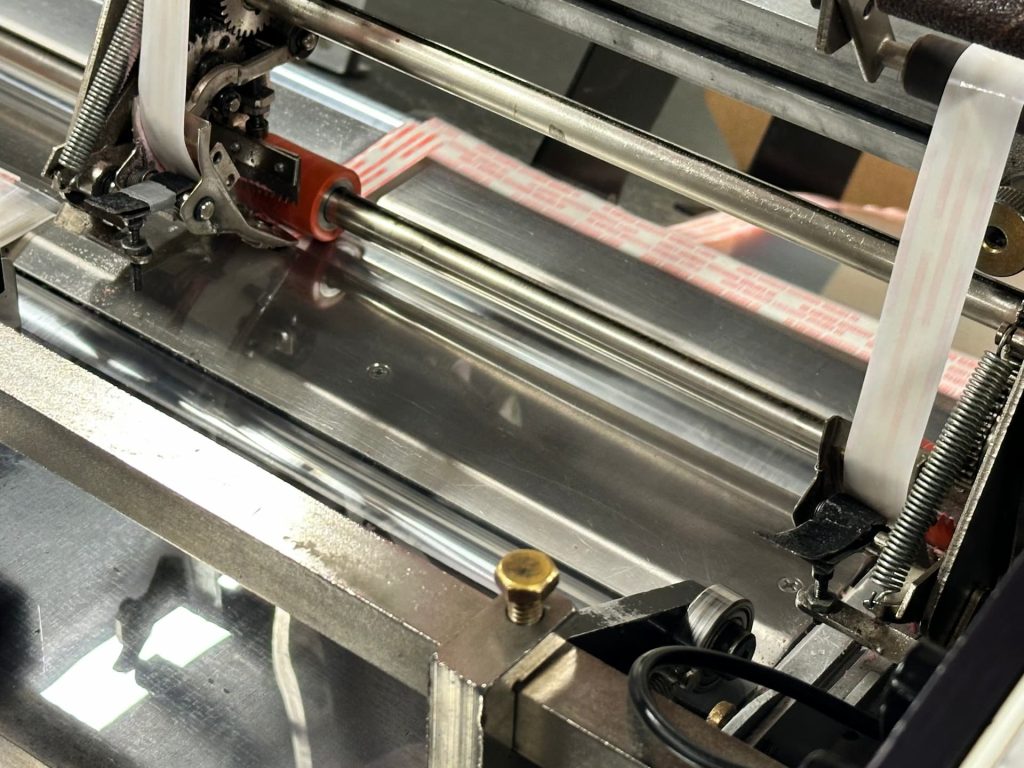

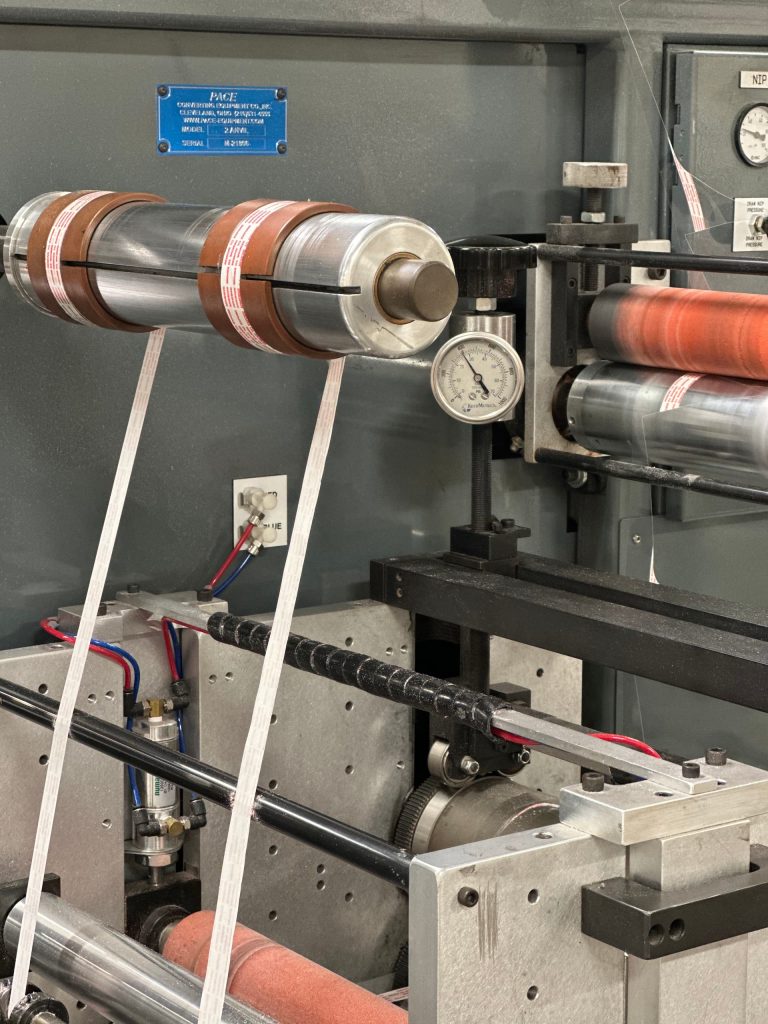

Our rotary die-cutting services provide high precision and intricate cut patterns, making it a great solution for industries that require high-speed accurate cuts from thin, flexible materials – specifically medical devices, electronics, and even aerospace. Rotary die cutting also ensures efficient material utilization which is key in reducing waste and keeping costs low.

Changes in design can be difficult and time-consuming with rotary die cutting due to the complex set up and implementation, so it’s important to consider whether a project will require changes when choosing a die-cutting method.

Materials: Paper, Foam, Foil, Plastics, Composites, Fiberglass, Metallic Foil, Polyester Films, Rubber, Adhesives, Fabric, Felt, Silicone, and Nonwovens

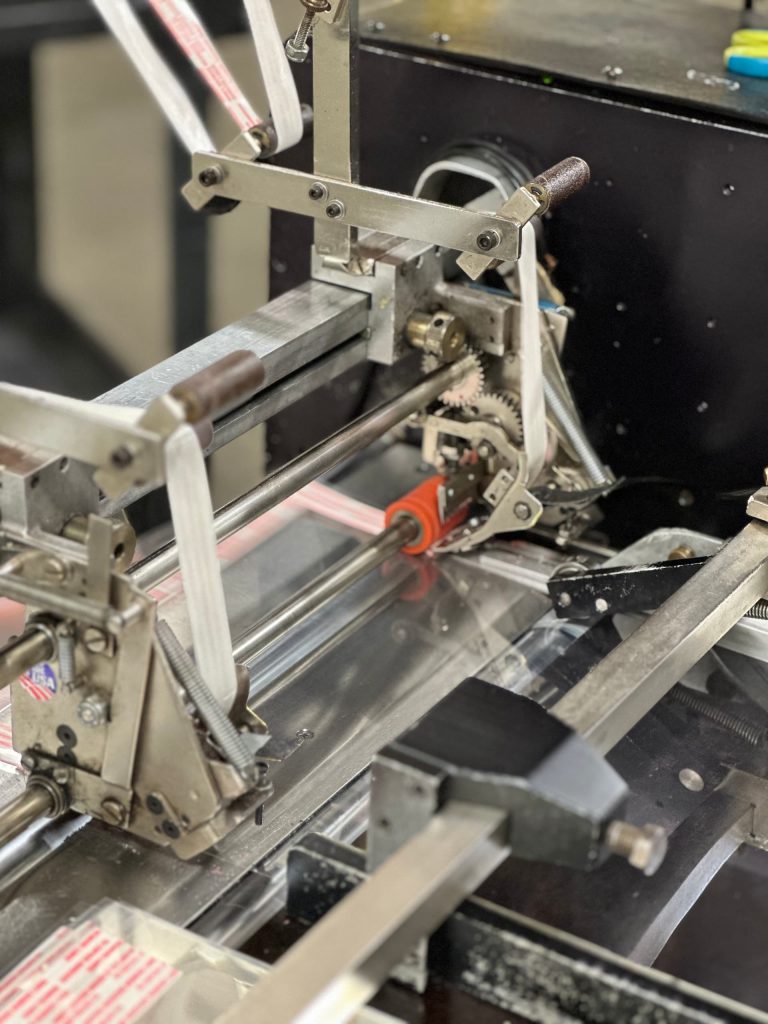

Our flat-bed die cutting services tend to be more adaptable for a smaller volume of product without having the high setup costs that can be associated with rotary die cutting. Flat-bed die cutting is also able to handle a wider variety of materials. Flat-bed die cutting can handle thicker materials, up to 0.5 inches, depending on which material is used.

Flat-bed die cutting provides much more flexibility with changes in design. It’s able to process shorter runs in a more cost-efficient way, so if your product requires many changes or tends to have variants throughout, it may be a better option over rotary die cutting services.

Materials: Vinyl, Polyester, Polypropylene, Polycarbonate, Polyethylene, Standard Paper, Coated Paper, Rubber, Foams, and Fabrics

Our kiss cutting services can be used together with rotary and flatbed die cutting. It can be used for a wide variety of products, specializing in materials with adhesive backings. This can include branding stickers, vehicle decals, wall stickers, product labels, and barcodes and shipping labels. It can be particularly helpful in making protective films for heavy machinery and automotive manufacturing.

Materials: Metals, Plastics, Composites Materials, Rubbers, and Paper Products

Our male-female stamping can be incredibly useful, with an ability to accommodate a wide variety of tougher materials that other methods typically can’t accomplish. It can be used to create heat shields, vehicle frame components, and panels for vehicle interiors, making it an incredibly useful method for automotive manufacturing. It can also be used for device cases, heat sinks, and metal contacts and connectors, major components for many electronics.

Materials: Corrugated Cardboard, Paperboard, Plastics, Foams, Thin Metals, and Chipboard

We have experience cutting packaging for a wide variety of products and industries. Some of the products that we can help with include die-cut folding boxes like mailing boxes, gift boxes, or even retail packaging. We can also help with labels and tags that include clothing tags for retail shops and plastic price tag displays.

Our custom die-cutting services follow a 4-step process that starts with design, die creation, quality approval, and finally to production. First, our team will work with you to design the die-cut design and choose which material and method are best. This process normally takes 1-3 days to complete. Then, the die will be custom created to fit the precision needed for your products, which is typically a 2-7 day process. Next, we’ll ensure that the initial designs pass all quality testing and receive approval before moving to mass production. The timeline on this step will be based on how quickly the design is approved and we can move forward with processing. Finally, the product will be moved to production and we’ll make sure to meet your quantity and quality standards by the allotted deadline.

Whether you’re an aerospace manufacturer in Kansas or a producer of automotives in Missouri, Colvin-Friedman is your trusted die-cutting partner.