Preparing fibers for various applications can usually benefit from die cutting. Here at Colvin-Friedman, we have more than 75 years of experience processing and die-cutting fibers of all kinds and look forward to helping you either in the fiber preparation and cutting stage or into the fabric stage as well.

Some of the most common fibers we see in projects for our clients include:

Among die-cut materials, foam is particularly unique and presents a number of specific challenges to the die cutting process. Some of the most pressing concerns associated with foam die-cutting are outlined below, along with some best practices to ensure the efficacy of the progress.

We use specialized coatings or resins to bind fibers before cutting as needed, or adjust cutting speed and pressure to minimize fraying.

We use one of two options: either cooled tools or external cooling systems to maintain fiber integrity.

Some fibers must point in a specific direction, so we use specialized clamping systems and cutting plans to maintain directionality.

While ultrasonic cutting is one option, experienced die cutters can also use multi-layer dies that ensure proper cuts of each layer.

Some fibers prove tougher to cut, and careful inspections will ensure pressure adjustments to match the cutting resistance observed.

Using anti-ionizing bars and humidity controls keeps fibers aligned and separated, increasing the effective run rate for production.

Special care must be taken with the waste of fiber die cutting processes, so we take special care that our ventilation and vacuum systems are functioning at maximum capacity before starting runs.

Or call Josh at (707) 769-4488

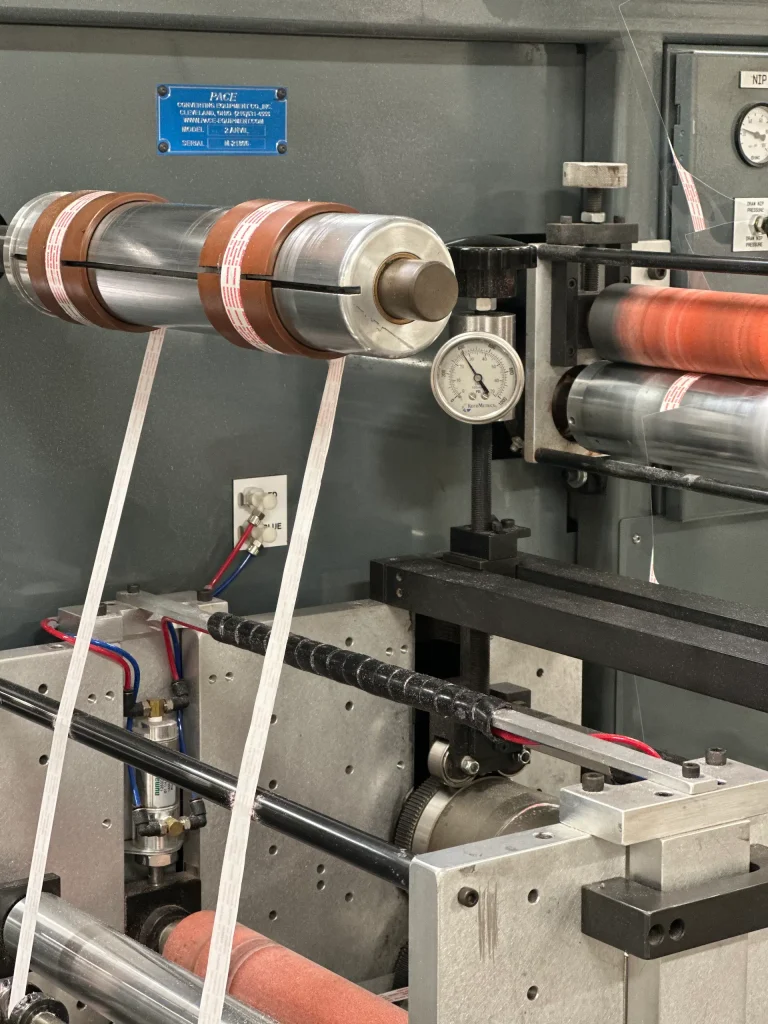

Even with the painstaking care we take to ensure that no issues arise during the fiber die cutting process, we are still able to ramp up runs to meet our clients’ demands, all while maintaining the tight tolerances to complex designs that they deserve. Our two most common processes are rotary and flatbed, and we’ve listed their output and input figures for review:

Lead Time (Average)

Maximum Production Rate

Maximum Product Thickness

Max Product Width

Tolerance Level

3 weeks

40,000 units/hr

0.015 inches (depending on tensile strength)

16 inches, but stripping capable

+/- 0.005 inches

3 weeks

2,000-4,000 units/hr

0.5 inches (depending on tensile strength)

40 inches

+/- 0.01 inches

Or call Josh at (707) 769-4488

Grouped more generally into synthetic and natural fibers, these are the building blocks of fabrics, carpets, filters, and much more. To give a better sense of the myriad options that can be handled with die cutting, we’ve put together two tables to outline the applications and what process we generally use when fiber die cutting specific types for our clients.

Polyester

Nylon

Polypropylene

Acrylic

Polyethylene

Strong, durable synthetic fiber with excellent resilience and moisture resistance. Easy to die cut and holds shape well.

Tough, abrasion-resistant fiber with high tensile strength. Good elasticity and moisture-wicking properties.

Lightweight, chemical-resistant fiber with good tensile strength. Low moisture absorption and easy to die cut.

Soft, wool-like fiber with excellent color retention and resistance to sunlight. Good insulation properties.

Flexible, lightweight fiber with high impact strength and chemical resistance. Easy to die cut but may require cooling.

Filtration materials, geotextiles, apparel

Automotive components, industrial fabrics, carpets

Geotextiles, filters, disposable products

Craft felts, clothing insulation, upholstery

Packaging materials, disposable medical textiles

Rotary die cutting

Flatbed die cutting

Rotary die cutting

Flatbed die cutting

Rotary die cutting

Polyethylene Terephthalate is a common type of thermoplastic and is a member of the polyester family. It has a number of versatile forms, as well as applications across multiple industries.

Polyethylene Terephthalate in its primary state is generally colorless and can be cut with different techniques depending on thickness. The most common varieties of Polyethylene Terephthalate include:

Cotton

Wool

Hemp

Jute

Flax (Linen)

Soft, breathable natural fiber with good absorbency. Biodegradable and easy to die cut, but may fray.

Natural protein fiber with excellent insulation and moisture-wicking properties. Resilient and flame-resistant.

Coarse, strong natural fiber with good insulating and antistatic properties. Biodegradable and low-cost.

Soft, wool-like fiber with excellent color retention and resistance to sunlight. Good insulation properties.

Strong, absorbent natural fiber with good heat conductivity. Resistant to static and lint, but may fray when cut.

Natural fiber composites, eco-friendly products, apparel

Insulation, felts, high-end apparel

Geotextiles, filters, disposable products

Eco-friendly packaging, geotextiles, composites

High-quality textiles, composites, insulation

Rotary or flatbed die cutting

Flatbed die cutting

Flatbed die cutting

Rotary die cutting

Flatbed die cutting

If you would like more information about our custom die-cutting services, process, or product capabilities, please use the number below to call our Vice President, Josh Rodman. If you would like to receive a free project quote, click the button below.

Or call Josh at (707) 769-4488

We have been a leading provider of die cutting services for over 75 years. Trust us to provide the customer service of a small business with the capabilities of a large organization.

1311 Commerce Street • Petaluma, CA 94954

Copyright © 2025 Colvin Friedman Company. All Right Reserved.