Colvin-Friedman’s Expertise in Custom Die Cut Parts

Colvin-Friedman has established itself as a leader in plastic die cutting since 1988. Our expertise in die cutting plastic has been a cornerstone of our operations, enabling us to provide high-quality, precision-engineered plastic parts to various industries.

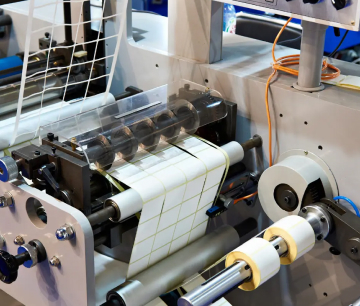

Kiss Cutting Plastic with Custom Die Cutting Services

Kiss cutting is a specialized die cutting process that pierces through the upper layers of a material while leaving the backing layer intact. This technique is often used in manufacturing labels, stickers, and other adhesive-backed products, where the precision of the cut is paramount. The process involves using digital die cutting machines that accurately control the pressure required to cut, creating a “crack and peel” surface for easy liner removal. This method is highly valued for its efficiency and precision, particularly in the timely assembly of parts and components in various manufacturing operations. The best die cutting in CA offers a multitude of options for kiss cutting and more.

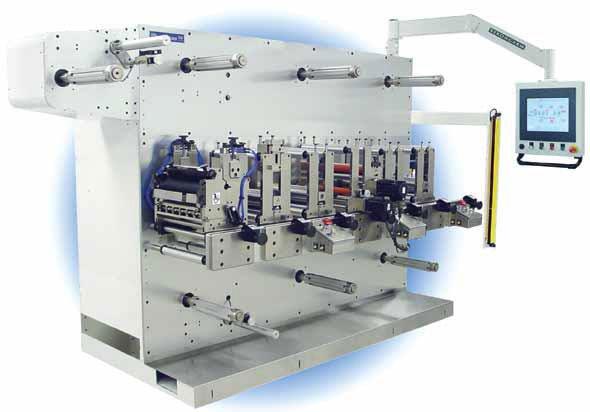

Preparation and Processing for Custom Rotary Die Cutting

Rotary die cutting is a sophisticated manufacturing process widely used in various industries to cut, shape, and create precise parts. This process involves several critical stages, from selecting appropriate materials to processing them correctly for optimal results. We will delve into the preparation and processing aspects of rotary die cutting, focusing on materials like Nomex, Vulcanized Fiber, and various paper products.

Rotary Die Cutting PETG Plastic: Die Cutting Services CA

When choosing materials for manufacturing processes like rotary die cutting, it’s essential to look beyond the inherent characteristics of the materials themselves. Understanding how a material interacts with a specific manufacturing process can significantly impact the efficiency, cost-effectiveness, and quality of the final product. Different materials respond uniquely to processes like cutting, forming, and finishing, making the choice of material a critical decision in the production line. Polyethylene Terephthalate with a Glycol Modifier (PETG) is a versatile thermoplastic, increasingly popular in various industries. Its properties make it particularly suitable for rotary die cutting, a common and efficient method for mass-producing precision parts.

Complex Rotary Die Cutting Solutions: When Flexible Dies Make More Sense Than Solid Dies

No two commercial die cutting services are the same. Custom solutions first mean understanding the needs and application of final products/parts and then finishing with a fully tailored die cutting service. We at Colvin-Friedman pride ourselves on being more than just the best die cutters CA offers; we are also problem solvers. One common issue many of our clients face is struggling with the how of a project, especially for complex pieces and parts. For jobs like this, we often turn to solid dies instead of flexible dies for the rotary die cutting process.

Can Die Cutting in CA Process Fabrics?

Die cutting is an efficient method for cutting shapes from various materials, including fabrics. The process involves using a die—a specialized tool

Custom Rotary Die Cutting Services in CA: How to Get the Best Parts

Rotary die cutting is a specialized manufacturing process known for its precision and efficiency. This process is integral to producing high volumes

Plastic Die Cutting Services: Kiss Cutting Materials

Kiss cutting is a specialized form of die cutting, representing a nuanced application within the broader die cutting process