For 75 years, Colvin-Friedman has been at the forefront of the die-cutting industry, serving diverse industries across California. From the tech innovation of Silicon Valley to automotive production in Southern California, our expertise and precision have made us the trusted partner for companies of all sizes throughout the state. Whether you need high-quality custom die-cut parts for electronics, medical devices, renewable energy, or consumer products, Colvin-Friedman delivers unmatched quality and reliability.

Our centralized location in Petaluma, CA, enables us to serve customers efficiently throughout the state. With strategic access to Northern and Southern California, we offer seamless support to all regions, helping businesses benefit from:

Our investments in advanced technology and diverse cutting techniques ensure we meet the unique needs of every project:

California’s industries are increasingly focused on reducing their environmental impact, and Colvin-Friedman helps achieve this:

California’s regulatory landscape for die cutting is complex, requiring compliance with environmental, safety, and product standards across various industries. Expertise in these regulations helps ensure quality, sustainability, and a competitive edge for manufacturers.

Or call Josh at (707) 769-4488

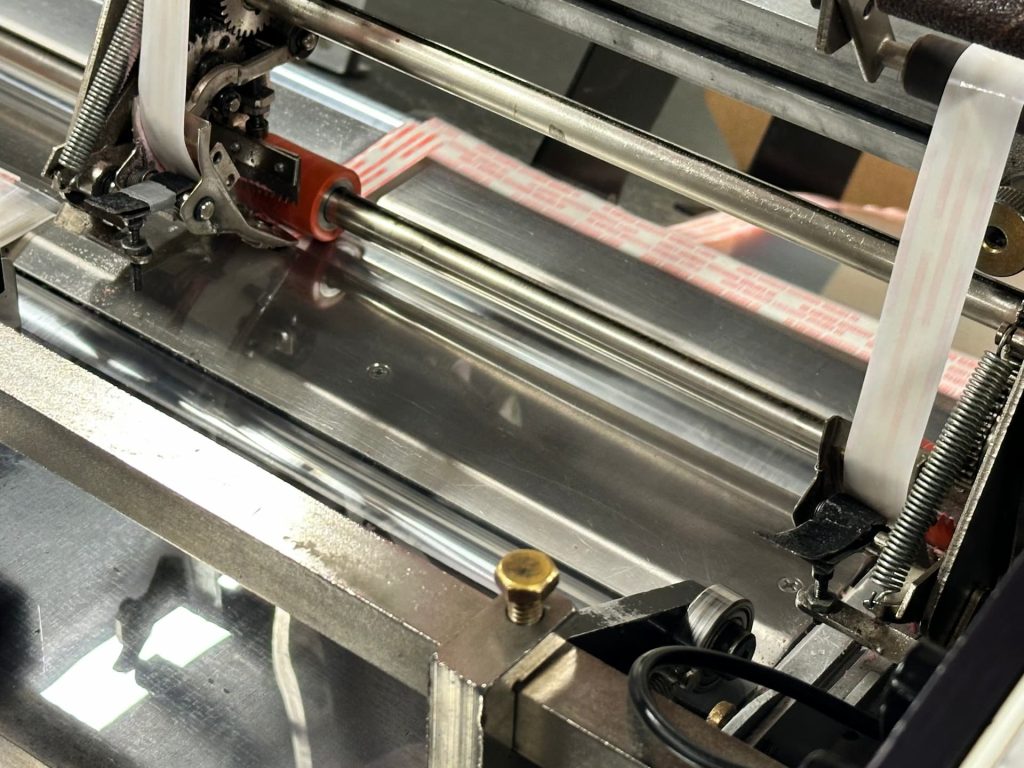

While leather is a popular material for a wide variety of products, ranging from shoes to holsters, harnesses and more, there is no perfect source. Unlike synthetics, suppliers can offer ranges of thicknesses and they are measured in ounces. While 1/64th of an inch per ounce might not seem like much, it means that a popular method for large-scale die cutting, the rotary press, is not a feasible option, even for the thinnest natural materials.

Instead, leather die cutting should be performed using either a sheet metal rule process or a flat bed process. Which one makes the most sense depends on the expected production volume, intricacy of cuts or designs and the type of leather. If you are still considering materials for your product, the following are common weights and applications:

Proximity and Turnaround Time

Face-to-Face Collaboration

California-Specific Expertise

Lower Supply Chain Emissions

Customer Support Availability10-12

Customization Flexibility

Local proximity allows for faster prototyping and delivery, reducing production delays.

Direct, in-person support for complex projects, ensuring clear communication and problem-solving.

Familiarity with local regulations and compliance, especially for industries like automotive and medical devices.

Shorter transportation distances reduce the carbon footprint and logistics costs.

Local support with same time zone, ensuring quick responses to inquiries and needs.

Greater flexibility for custom orders, including prototype adjustments, due to close proximity.

Shipping from out-of-state may introduce delays and increased lead times.

Remote-only collaboration often leads to miscommunication and extended timelines.

Limited understanding of California’s specific regulatory landscape.

Cross-state transportation increases emissions and overall shipping expenses.

Potential time zone differences may result in slower response times and service gaps.

Less flexibility for changes during production due to distance.

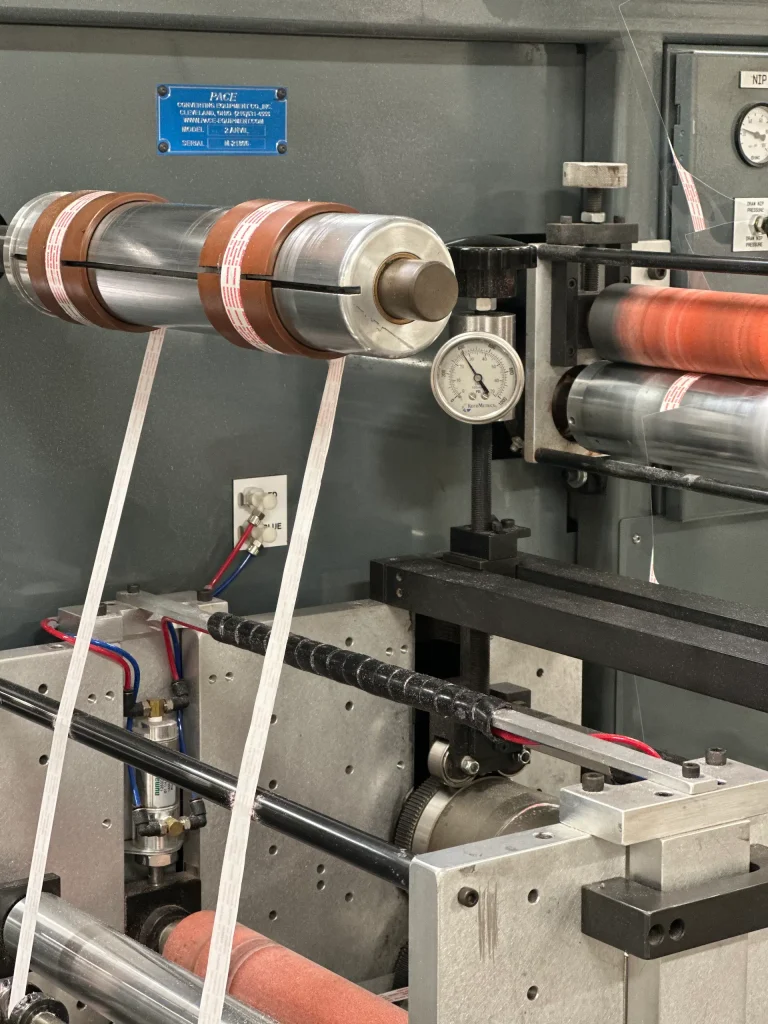

Steel rule dies are utilized in flatbed die cutting to affordably and efficiently maintain an accurate die cut. Steel rule die-cutting uses a specific type of die made of hardened steel rule, pressed into the back of laser etched high quality plywood and/or acrylic.

We can generally utilize steel rule dies to cut products within the following parameters. We may be able to cut projects outside of these parameters, depending on the size and material. For projects under this range, we may recommend rotary die-cutting. If we cannot cut your product, we will refer you to someone who can.

Automotive & Aerospace

Medical Devices and Healthcare

Renewable Energy

We understand that each industry has its unique challenges and specific requirements. Our approach focuses on tailoring our services to best suit each customer’s needs:

Our capabilities include cutting a wide range of materials commonly used across California’s industries. We specialize in:

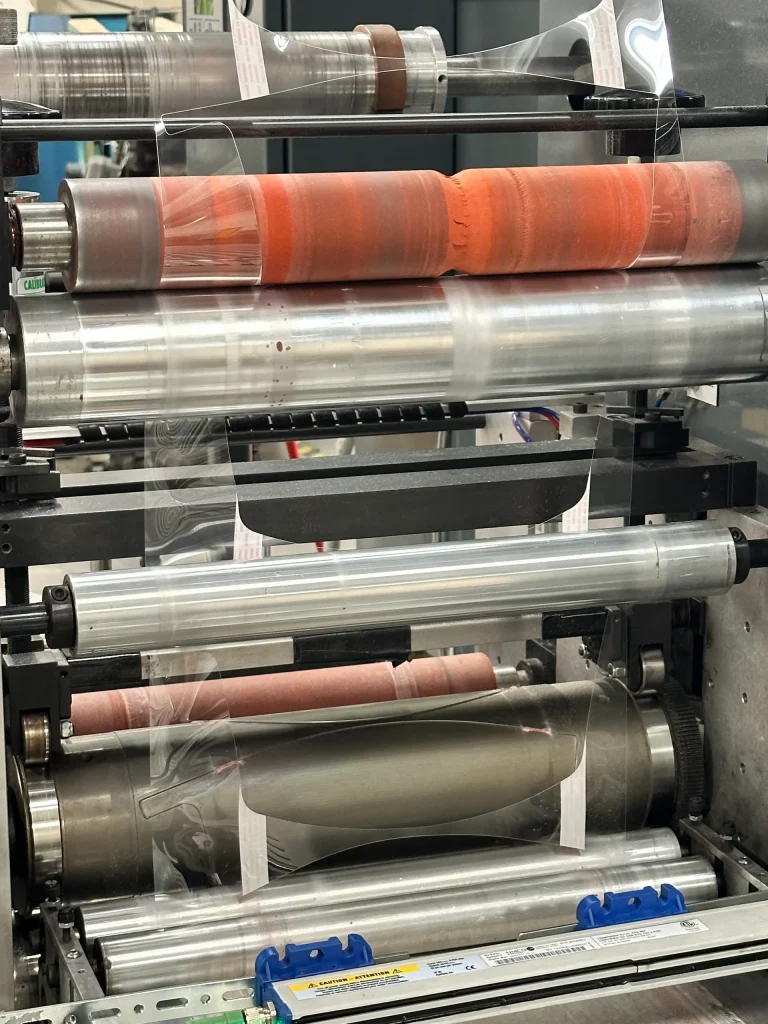

Our rotary die-cutting services are especially well-suited for high-volume orders where consistency is key, while flatbed die cutting offers flexibility for handling thicker and more varied materials. Our machinery can achieve tolerances as tight as ±0.005 inches, ensuring the precision needed for demanding applications.

Colvin-Friedman has the capacity to handle large-scale production runs without sacrificing quality. Our rotary presses can produce up to 40,000 units per hour, making them ideal for high-volume needs. Our quality control processes include strict standards with each part inspected to ensure it meets client specifications. We also employ SCADA and PLC systems to maintain efficiency and ensure consistent quality across the entire production run.

Whether you’re a high-tech innovator in Silicon Valley, a medical device producer in Los Angeles, or a solar company in San Diego, our expertise and dedication make us the ideal die-cutting partner.