At Colvin-Friedman, we have been producing top-quality die-cutting components since 1949, with many of those components being used for OSHA applications. Our understanding of this industry leads us to three primary areas of focus: precision in cutting, deep expertise in materials commonly used for OSHA products, and the continual development of best practices to ensure components are produced to exacting tolerances. Below we’ve listed some of our capabilities, best practices, and more information on our process. If you would like a quote on your occupational health and safety die-cutting needs, fill out the quote form or call our Vice President, Josh Rodman at 707-769-4488.

Or call Josh at (707) 769-4488

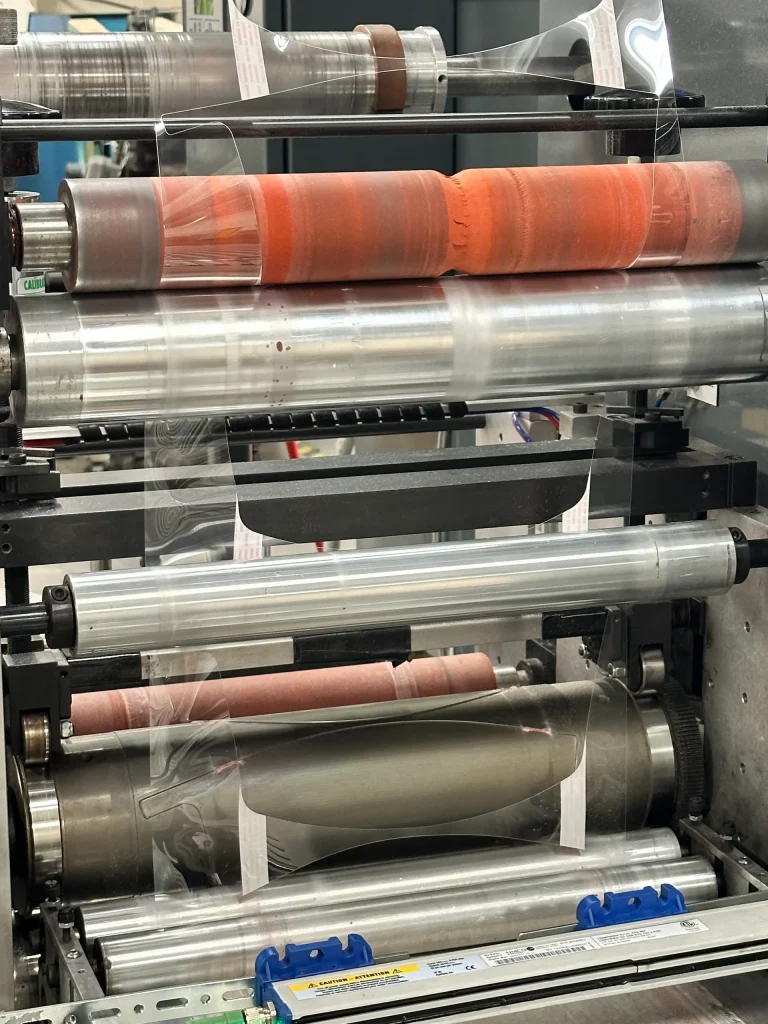

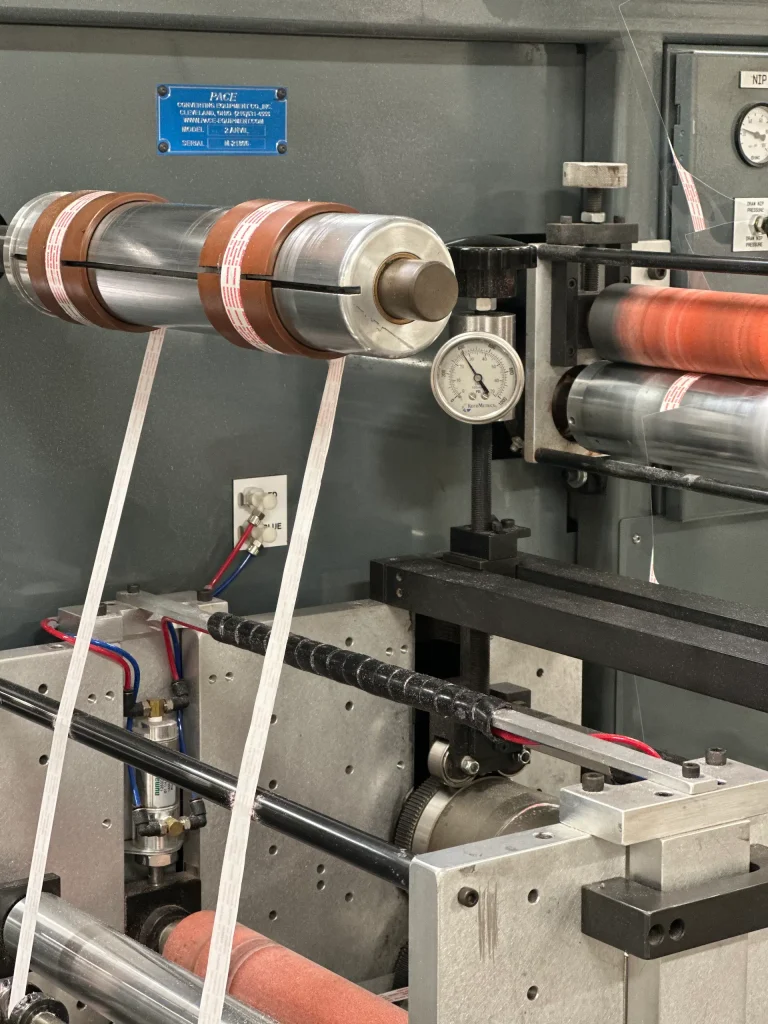

Below we’ve listed categories of material that we can die cut, with an emphasis on explaining the differences in methods: rotary die cutting can be used for very high-speed production, but the level of detail and thicknesses of material that can be processed is different than that of flatbed steel-rule die cutting.

Optical Materials

Plastic Films and Sheets

Foam and Cushioning Materials

Rubber and Elastomers

Abrasive Materials

Thin lens overlays, Protective films, Disposable face shield covers

Lens care product packaging, Thin protective overlays, Instruction manual pages

Thin foam gaskets, Adhesive-backed foam tapes

Thin gaskets, Membrane switches, Thin seals

Thin sanding sheets, Fine polishing films, Thin abrasive overlays

Thin polycarbonate films, PET optical grade films, Removable protective layers

PET (polyethylene terephthalate), LDPE (low-density polyethylene), Thin PETG sheets

Thin closed-cell polyethylene foam, Adhesive-backed foam tapes up to .015″

Thin silicone sheets, Thin neoprene gaskets, Elastomeric films up to .015″

Thin aluminum oxide sheets, Fine-grit sanding films, Thin non-woven abrasive materials

Rotary for high-speed cutting of thin films up to .015″; Flat press for thicker materials

Rotary for high-speed cutting of films up to .015″; Flat press for thicker materials or intricate designs

Rotary only for very thin foams up to .015″; Flat press for all thicker foams

Rotary for thin sheets up to .015″; Flat press for thicker materials and most OHS applications

Rotary for materials up to .015″; Flat press for thicker or more aggressive abrasives

We are also capable of working with far more material thicknesses with our flatbed die-cutting processes. Below are some

of the expanded capabilities you might find with these production systems in use at Colvin-Friedman.

Optical Materials

Plastic Films and Sheets

Foam and Cushioning Materials

Rubber and Elastomers

Abrasive Materials

Excellent

Excellent

Excellent

Excellent

Excellent

Full-thickness lenses up to 0.5”, Face shields, Multi-layer protective eyewear

Thick protective overlays, Robust face shield materials, Lens care product containers

Goggle padding, Helmet inserts, Ear protection components, Thick cushioning materials

Thick valve components, Robust seals and gaskets, Complex respirator parts

Thick sanding discs, Durable polishing pads, Multi-layer abrasive sheets

Or call Josh at (707) 769-4488

Since each of the materials used in creating occupational health and safety products has differences in tensile and compression strength, chemical and temperature resistance, and more, working with each one requires a different set of conditions. Below, we’ve listed what helps Colvin-Friedman maintain its standard of excellence and quality control.

Optically clear edges on cut lenses

Preventing scratches during the cutting process

Maintaining designed curvature

Use polished and ultra-sharp dies, and when necessary, implement polishing procedures.

Use protective films when necessary and maintain clean room protocols.

Use specialized curved dies and ensure temperatures meet material specifications to reduce warping.

Avoiding micro-cracks and fissures

Preventing static build-up and debris accumulation

Maintaining stability in dimensions for films

Maintain optimum pressure and test different speeds for cutting on prototypes. Use extremely sharp dies designed for specific plastic types.

Use ionizers throughout the production cycle and include anti-static packaging for finished parts before inventory transfer.

Maintain temperature and humidity per material guidelines and select backing materials that help maintain enough rigidity for die cutting.

Achieving consistent density across cuts

Cutting intricate shapes without tearing

Preventing compression set

Use specialized blade angles when designing foam dies and control speed to minimize compression issues during the cutting process.

Complex shapes often require multi-stage cutting processes, one cut for the initial separation and a second through cut.

As with other materials, provide adequate time for the materials to come up to the temperature and humidity of the storage area. Perform frequent checks for resilience and after-cut design tolerances.

Avoiding edge deformation

Preventing sticking of cut parts to dies

Maintaining tolerances in flexible materials

Colvin-Friedman uses precision-ground dies and ensures that cutting pressure and speed properly match each type of elastomer.

Release agents are commonly used on cutting dies to ensure part separation while air ejection systems can also be used.

Similarly to edge deformation, maintaining consistent pressure and speed is crucial and can be done by implementing stabilizing materials and tracking cuts with quality control personnel.

Managing tool wear

Managing dust creation

Achieving clean cuts without layer separation

Rely on hardened steel and carbide dies along with creating a replacement schedule.

Cutting stations should include dust collection systems and wet-cutting techniques can also help.

Consider multi-layer cutting dies and, as always, optimize cutting pressure and speed.

Or call Josh at (707) 769-4488

Since each of the materials used in creating occupational health and safety products has differences in tensile and compression strength, chemical and temperature resistance, and more, working with each one requires a different set of conditions. Below, we’ve listed what helps Colvin-Friedman maintain its standard of excellence and quality control.

Experience

Capabilities

Materials

Quality Control

Turnaround Time

Capacity

Additional Services

Compliance

Financial Stability

Years in OHS/Optical Manufacturing

Types of Die-Cutting Machines

Maximum Die Cutting Size

List of Optical-Grade Materials Handled

Inspection Methods Used (e.g., automated vision systems)

Average Prototype Turnaround

Average Production

Annual Production Capacity

Optical Design Assistance

Assembly Services for OHS Products

OSHA Standards Compliance

Years in Business

75 years in complex die-cutting like medical and electronics

Rotary, flatbed

16-inches rotary, 40 inches flatbed

See table above

Vision systems, statistical controls, micrometers, calipers, various fixtures

1-3 days

3 weeks

Millions

Can provide design assistance to maximize quality control and die-cutting throughput

Assembly service and inventory management system integration are available.

Complies with all OSHA standards

75+

Whether it’s face masks for personal protective equipment or gaskets to protect workers from noxious chemicals, Colvin-Friedman has been proudly producing the parts that make up crucial pieces of occupational safety and health equipment. If you’re looking for a quote for your OSHA die-cutting needs, please don’t hesitate to fill out the short form for a tailored response. You can also call our Vice President Josh Rodman at 707-769-4488 for answers to any questions you might have or to start the process.

Or call Josh at (707) 769-4488