With seven decades of experience, Colvin-Friedman knows how effective paper die cutting can be for precision material shaping. For each run, our experts create a custom die to meet your specific project requirements that can be used repeatedly, producing clean edges on cut materials. If you need a paper machining process that combines precision, versatility, efficiency, and customization capabilities, die cutting from Colvin-Friedman is fit for purpose, serving industries as varied as packaging and crafting.

Paper die-cutting only works as an outsourced process if the supplier and the company are in complete alignment through all steps. Colvin Friedman is in constant contact with each customer through the following four pre-cut stages of the process:

Discuss project requirements like design, quantity, and lead time

Assess any initial designs or specifications already produced.

Consider material options based on cost and quality concerns.

Refine concept for optimal die design.

Consider implementing any changes for reduced costs/improved efficiency.

Approve any prototypes or samples prior to production start.

Receive quote specifying all setup fees, per-unit costs, and any additional charges.

Review quote for agreed-upon materials, quantities, and delivery timeline.

Confirm the production schedule and any critical deadlines.

Agree on quality control measures and tolerances.

Examine any test run examples if requested.

Or call Josh at (707) 769-4488

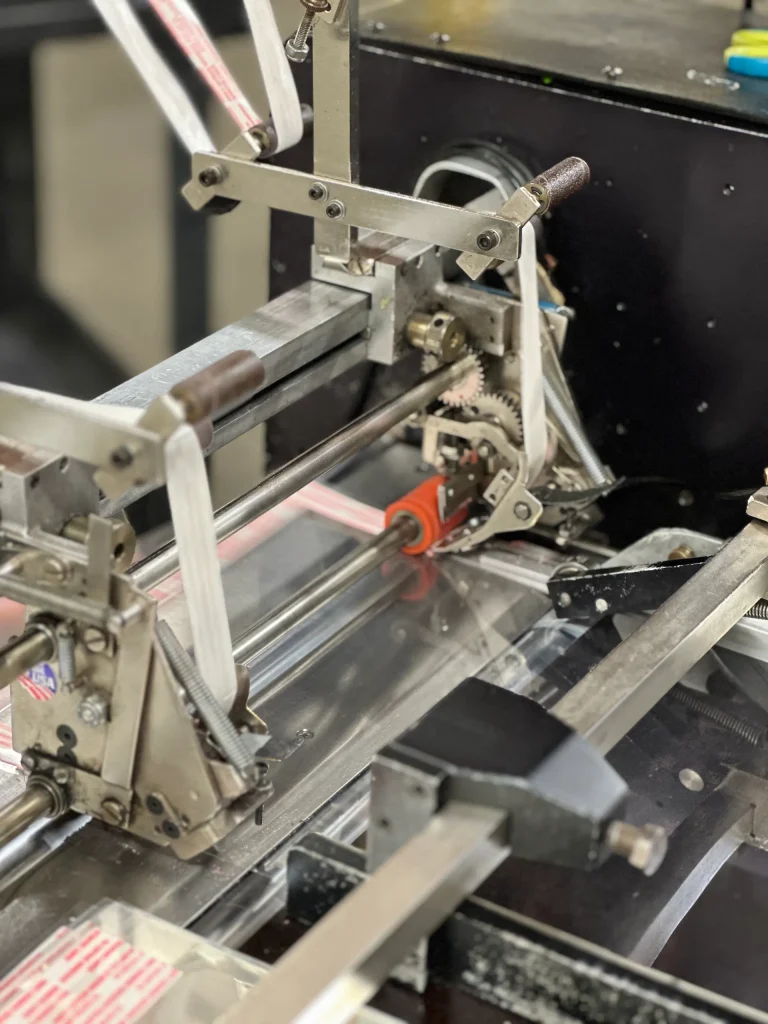

While the best choice of steel die to use for paper cutting is often a question left in the hands of the draftsman or project manager, there are three common types of die cutting machines, or presses, that are used for paper and cardboard. Each has its own benefits, ranging from the thickness of material to be handled to design detail possible.

Paper Types

Thickness Range

Best For

Production Speed

Precision

Complexity of Cuts

Typical Run Sizes

Setup Time

Material Waste

Versatility

Lightweight papers, Label stock, Thin cardstock

0.004″ – 0.014″

High-volume production, Thicker materials

Very High

High

Simple to Very Complex

100,000+ pieces

Medium

Low

Best for thinner materials

Cardstock, Corrugated board

0.014″ – 0.079″

Complex designs, Short to medium runs

Medium

Very High

Simple to Moderate

1,000 – 100,000 pieces

Short

Low to Medium

Highly versatile

Or call Josh at (707) 769-4488

Paper, cardstock, and cardboard tend to be thinner materials, but that same lack of thickness can lead to a wide variety in terms of customization. Some of the myriad options available to package designers, corporate artists, and others include:

There are many ways to cut paper or card stock to customers’ specifications, so select paper die cutting when:

More specifically, we’ve compared paper die cutting to alternatives and included some sample applications below:

Laser Cutting

Amorphous PET (APET)

Crystalline PET (CPET)

PETG is a modified variety of PET that has greater flexibility, impact resistance and ease of processing, along with higher clarity and gloss. It is a common substitute for polyester.

APET possesses high clarity and gloss and is rigid with strong impact resistance. Additionally, it has strong heat resistance.

CPET is a very opaque variety of PET. Its melting point is even higher than APET’s, and is well suited for high heat environments.

Any thickness paper or cardboard can be processed with paper die cutting. However, some types of cardboard may be a better fit for flatbed die cutting, which is a better fit for lower volume production runs than rotary die cutting.

As in the section on types of die cutting, it largely depends. The person who can give you the most accurate answer is the supplier’s project manager.

The longest periods of time for most paper die cutting projects come during the planning phase, where any potential issues are ironed out. Lead times of a little over a week are common, giving enough time for the supplier and a company to agree on a design, tolerances and other specifications, then for an expert craftsman to create the die that will be used for the product.

The level of precision with paper die cutting is unmatched by other cutting processes because the entire system is automated based on customer design and experienced technicians punching out intricate shapes.

If you would like more information about our custom die-cutting services, process, or product capabilities, please use the number below to call our Vice President, Josh Rodman. If you would like to receive a free project quote, click the button below.

Or call Josh at (707) 769-4488

We have been a leading provider of die cutting services for over 75 years. Trust us to provide the customer service of a small business with the capabilities of a large organization.

1311 Commerce Street • Petaluma, CA 94954

Copyright © 2025 Colvin Friedman Company. All Right Reserved.